BGA Rework Equipment

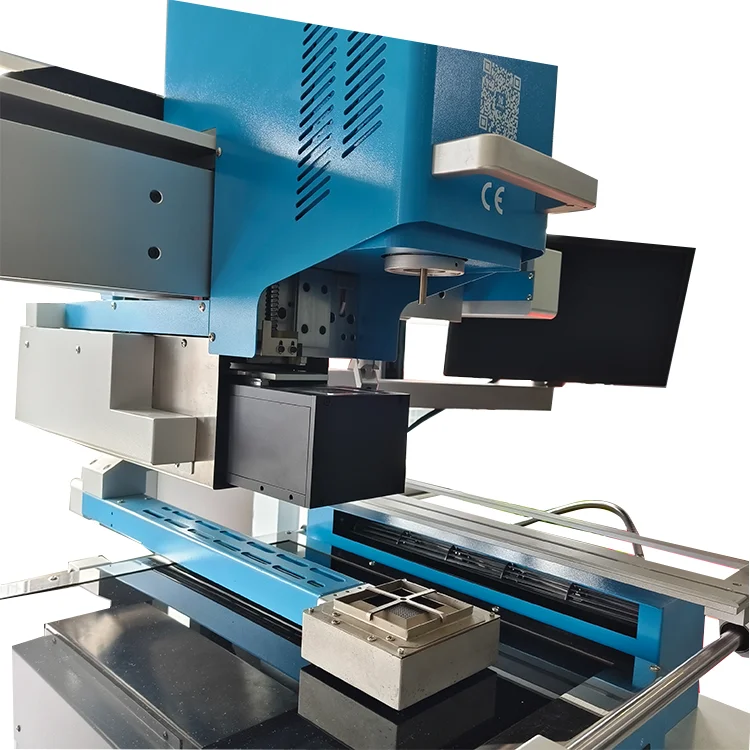

The BGA rework equipment is an optical alignment BGA rework station that used in laptop motherboard repair and smartphone PCB repair and a wide range of electronic component rework.Equipped with three independent temperature zones(top heater,bottom heater and infrared preheating zone),HD touch screen,optical alignment CCD camera,laser positioning pointer,cross-flow cooling fan,HD display,and an automatic vaccum pickup device.Ensuring accurate alignment and reliable rework performance.

Description

Products Description

The BGA rework equipment is an optical alignment BGA rework station DH-A6 that used in laptop motherboard repair and smartphone PCB repair and a wide range of electronic component rework. Equipped with three independent temperature zones(top heater, bottom heater and infrared preheating zone), HD touch screen,optical alignment CCD camera, laser positioning pointer, cross-flow cooling fan, HD display, and an automatic vaccum pickup device. Ensuring accurate alignment and reliable rework performance.

Application industries for optical alignment BGA rework station:

1. Consumer Electronic Manufacturer: smartphone PCB repair, laptop motherboard repair, gaming consoles (PS, Xbox);

2. Computer & IT Hardware: graphics cards (GPU repair), CPU sockets and chipset BGA packages;

3. Automotive Electronics: ECU (Engine Control Unit), ADAS control modules, Automotive sensors and controllers;

4. Industrial Control & Automation: PLC control board, inverter and motor control PCBs, industrial robots and machinery PCBs;

5. Medical Electronis: imaging device control boards, patient monitoring systems;

6. Repair Centers & Technical Service Shops: motherboard repair shops, mobile phone repair centers, professional PCB repair business;

7. Education & Research Institutions: university electronics laboratories, R & D centers, Microelectronics teaching and training facilities;

8. Aerospace & Defense Electronics: radar and navigation control modules, communication equipment;

9. EMS / OEM / ODM Factories: electronics manufacturing services (mass production line rework), prototype development and engineering labs.

Detail Pictures

Products Specification

|

Item

|

Parameter

|

|

Power Supply

|

AC220V±10% 50/60Hz

|

|

Total Power

|

11000W

|

|

Top heater

|

1200W

|

|

Bottom heater

|

1200W

|

|

IR preheating area

|

8000W

|

|

Operation mode

|

Fully automatically disassemble,suction,mounting and soldering

|

|

Chip feeding system

|

Automatic receiving, feeding, automatic induction (optional)

|

|

Temperature profile storage

|

50000 groups

|

|

Temperature control

|

K-type Sensor,Closed loop and 8~20 segments for temperature controlling program

|

|

Temperature accuracy

|

±2 ℃

|

|

Placement Accuracy

|

+/-0.01mm

|

|

Safety guard

|

pressure sensor +emergency knob,double-guard

|

|

PCB size

|

Max700*620 mm Min 22*22 mm

|

|

Net weight

|

150kg

|

|

BGA chip

|

2x2-65*65mm

|

|

Minimum chip spacing

|

0.15mm

|

|

External Temperature Sensor

|

5 pcs(optional)

|

|

Machine type

|

Desktop table (optional)

|

|

Dimensions

|

L1050*W1130*H1070 mm

|

Products Features

1. High-definition touchscreen interface, PLC control, and instantaneous curve analysis function. Real-time display of set and measured temperature curves, with the ability to analyze and correct the curves.

2. Employs a stepper motion control system: stable, reliable, safe, efficient, and highly automated; utilizes a high-precision digital image alignment system; the PCB board positioning uses a V-groove and linear slide, allowing for fine-tuning or rapid positioning along the X, Y, and Z axes-convenient, accurate, and suitable for different PCB layouts and PCB sizes.

3. A flexible and convenient movable universal clamp protects the PCB board, preventing damage to edge components and PCB deformation, and accommodates rework of various BGA package sizes.

4. Equipped with various sizes of alloy air nozzles, which can rotate 360 degrees for easy installation and replacement.

5. Each upper and lower heating zone can be set with 8 temperature segments. A large number of temperature curves can be stored and retrieved for different BGAs. Curve analysis, setting, and correction can also be performed on the touchscreen.

6. The three heating zones use independent PID algorithms to control the heating process, resulting in more uniform and accurate heating.

7. A high-power cross-flow cooling fan rapidly cools the PCB board to prevent deformation, enabling intelligent automated control of the mounting, soldering, and disassembly processes.

8. A voice-activated "early warning" function alerts operators 5-10 seconds before disassembly or soldering is complete. After the upper and lower hot air stops heating, the cooling system activates and automatically stops cooling once the temperature drops to room temperature. This prevents the machine from aging after overheating.

9. Features material receiving and feeding functions, making machine operation simpler, more convenient, and improving efficiency.

FAQ

Q: Are you a manufacturer or trade company?

A: We are a manufacturer specilize in BGA rework station, X-ray counting machine, X-ray inspection machine, automatic equipment, SMT related equipment and etc.

Q: Where is your factory?

A: 4th F 6B, Shengzuozhi Technology Park, Xinqiao/518125, Bao'an, Shenzhen, GUangdong, China.

Q: What service can you privide?

A: 1. Professional after-sales service, free technical consultation and video demonstration available. 2. 1-year warranty for the entire machine (excluding consumables). 3. OEM and ODM services are welcomed. 4. Payment methods: T/T, Western Union, etc. 5. Fast delivery options include FedEx, DHL, UPS, EMS, etc.

Q: What is an optical BGA rework station?

A: An optical BGA rework station is an advanced machine used to remove, align, and solder Ball Grid Array (BGA) chips on printed circuit boards (PCBs) with high precision. It is equipped with a CCD optical alignment system, which uses cameras and imaging software to display the chip's solder balls and PCB pads on a screen. This allows the operator to align the component accurately in real time, ensuring perfect placement before soldering.

Q: How can I buy machine from you?

A: 1. Contact us online or via email with your product requirements and technical questions. Our sales team will respond promptly with detailed information. 2. We discuss and confirm the final pricing, delivery terms, shipping method, payment method, and all other commercial details. 3. A formal Proforma Invoice (PI) will be provided for your review and confirmation of the order details. 4. You proceed with the payment according to the method stated on the Proforma Invoice. Please send us the payment slip for verification. 5. Upon receipt of full payment, we begin preparing and arranging your order strictly according to the PI specifications. Every unit undergoes a 100% quality inspection before shipment. 6. Your goods will be shipped via international express courier, air freight, or sea freight based on your preference. Tracking information will be provided immediately upon dispatch.