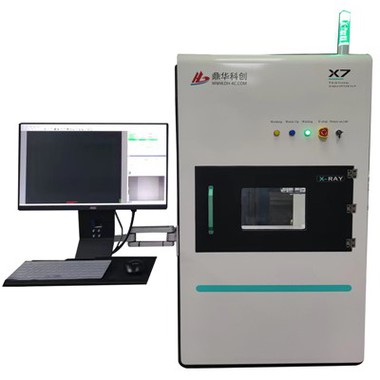

Xray Pcb Inspection Machine

This advanced PCB X-Ray Inspection Machine DH-X9 is engineered to deliver definitive quality control for modern electronics manufacturing. It seamlessly combines high-resolution imaging with intelligent automation to detect hidden defects like BGA voids and solder bridges with unmatched accuracy.

Description

Products Introduction

Precision Unveiled: The Advanced PCB X-Ray Inspection Machine for Uncompromising Quality Control

In the intricate world of electronics manufacturing, seeing is not just believing-it's ensuring. Defects hidden from the naked eye, such as BGA voids, solder bridging, or insufficient through-hole fill, can compromise the integrity of an entire assembly. Our state-of-the-art PCB X-Ray Inspection Machine is engineered to reveal these hidden flaws with unparalleled clarity and efficiency, transforming your quality assurance process from guesswork into guaranteed precision.

Technical Specifications & In-Depth Features

1. Superior Motion & Imaging System for Complete Coverage

Our PCB Xray Machine is built on a fully motorized platform designed for maximum access. The large-diameter (530mm) stage provides ample space for oversized panels. Its precise XY movement and full 360° rotation ensure every solder joint can be brought to the center of the inspection field. Crucially, the image detector's 60-degree tilting capability allows for side-angle inspection of vertical connections, making it exceptionally effective for identifying BGA soldering defects (e.g., head-in-pillow, voids) and through-hole pin soldering issues that are invisible from a top-down view.

2. High-Stability Core Imaging Components

At the heart of the system is a sealed microfocus X-ray source. This closed-tube design is renowned for its long operational lifespan and stable performance, eliminating the need for routine maintenance like oil changes required by older open-tube systems. It works in tandem with a high-resolution digital flat panel detector to deliver sharp, real-time images with excellent contrast, allowing you to discern minute details as small as a few microns.

3. Intelligent Software for Enhanced Productivity

Visual Navigation & Automated Programming: The intuitive software interface features a navigational overview window. Simply click on a location, and the stage automatically moves there. You can create, save, and edit step-by-step inspection programs for different board types, enabling fully automated batch inspection.

Comprehensive Digital Management & Integration: Every inspection program and its corresponding X-ray images are saved in a structured "Rework Digital Library" for traceability and easy recall. The system supports custom integration with factory MWS (Manufacturing Execution Systems) and ERP platforms, allowing test data to flow directly into your production management dashboards.

4. Engineered for Diverse Industrial Applications

This versatile inspection solution is ideal for a wide range of applications beyond standard PCBAs:

Automotive Electronics: Inspecting safety-critical ECU modules and dense interconnects.

Aerospace & Defense: Verifying the integrity of high-reliability assemblies.

LED Manufacturing: Checking solder coverage under large LED chips on aluminum substrate boards.

Power Electronics: Analyzing thermal pad voids and busbar soldering in power modules.

Visual Guide to Key Features (Conceptual Illustration)

| Feature | Description | Visual Benefit |

|---|---|---|

| Multi-Axis Stage & Tilting Detector | Diagram showing a PCB rotating 360° on the XY stage while the detector arm tilts to 60°. | Demonstrates the ability to inspect any joint from any angle, eliminating blind spots. |

| High-Resolution Imaging | A side-by-side comparison: a blurry X-ray image vs. a crisp image from our system, clearly showing individual BGA balls and void defects. | Highlights the exceptional image clarity that enables accurate defect diagnosis. |

| Automated Program Workflow |

A screenshot sequence of the software: 1) Loading a board layout, 2) Defining inspection points, 3) Running an automatic scan, 4) Displaying a summary report with NG markers. |

Illustrates the path from setup to automated, report-driven inspection. |

Example images

Why Choose Our PCB X-Ray Inspection Solution?

This system is more than just an inspection tool; it's a strategic asset for your production line. It dramatically reduces escape rates of latent defects, lowers costly rework and field failures, and provides irrefutable process evidence for compliance and customer audits. By automating the most critical and repetitive aspects of quality control, it frees your skilled technicians to focus on analysis and process improvement, driving overall operational excellence.

Invest in certainty. Empower your production with definitive insight.

Our Company

Shenzhen Dinghua Technology Co., Ltd. is a national high-tech enterprise integrating the R&D, production, sales and service of X-ray counting machines, X-ray NDT machines, BGA rework stations, and automation equipment! We have the absolute strength to provide you with high-quality products, perfect services and advanced technical support.

Found in 2011, Dinghua Technology has been focusing on the R&D and production of X-RAY counting machines, X-ray NDT machines, BGA rework stations, and automated production equipment. The company takes "research and development as the foundation, quality as the core, and service as the guarantee" and is committed to creating "professional equipment, professional quality, and professional service"! At the same time, the company adheres to the development concept of "professionalism, integrity, innovation, and pragmatism" and has established a professional technical research and development team. It constantly absorbs and draws on domestic and foreign industry development experience, boldly explores, introduces new ideas, and realizes the transformation from traditional hardware combination to integration. The second revolution in the control industry, becoming a pioneer and leader in X-ray counting or NDT, BGA rework stations, and automation production equipment industries.

Company Honor Certificate