Xray For Electronics Voard

This PCB X-ray machine delivers precise non-destructive testing for electronics and manufacturing. As a versatile industrial X-ray machine, it features a tilting detector and programmable stage for multi-angle inspection—ideal for automotive ECU tester applications and PCB assembly analysis.

Description

Product Overview

Our state-of-the-art PCB X-ray Machine redefines precision non-destructive testing. As a versatile Industrial X-ray Machine, it delivers unparalleled capabilities for quality control and failure analysis across complex electronics and components.

Core Features & Advantages

1.XY-Axis Motion Stage: Enables extensive scanning coverage, significantly enhancing product inspection throughput and reliability.

2.60° Tilting Image Detector: Facilitates effortless observation of side-wall defects in components such as BGAs, ensuring comprehensive ECU tester-grade analysis for critical automotive electronics.

3.Real-Time Line Beam Source & Receiver: Utilizes a high-sensitivity Japanese HAMAMATSU sealed source coupled with a high-definition digital flat-panel detector for crisp, real-time imaging.

4.Visual Automated Navigation Window: User-friendly interface allows operators to quickly locate and zoom into inspection targets, streamlining the workflow.

5.Spacious Loading Platform: Features a large 550mm x 670mm inspection chamber, accommodating a wide range of product sizes.

6.Programmable Inspection Recipes: Ideal for high-volume automated inspection, boosting efficiency and ensuring consistent results batch after batch.

7.Digital Work Library Management: Save, edit, and manage inspection programs for repeatable and traceable quality checks.

8.S/ERP System Integration: Supports customizable connectivity for seamless data management and integration into smart factory systems.

Application Domains

This premium Industrial X-ray Machine is engineered for excellence in multiple sectors:

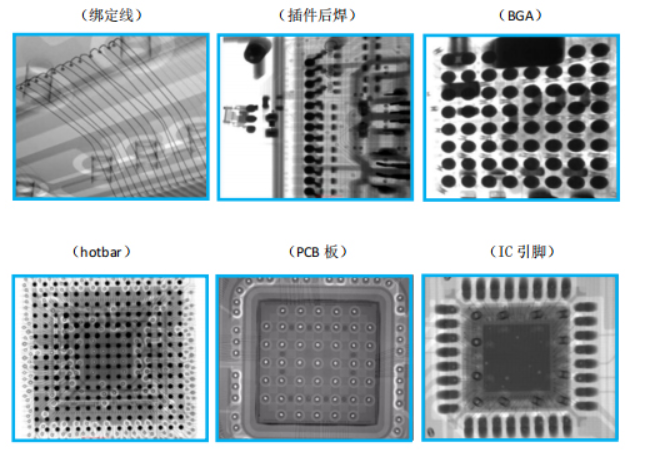

1.Semiconductor & Advanced Packaging: IC, BGA, CSP, Flip Chip inspection.

2.PCB & Assembly (SMT/DIP): Comprehensive PCB X-ray Machine for solder joints, voids, and component placement.

3.Automotive Electronics: Critical inspection for ECU tester applications, sensors, connectors, and control modules.

4.Automotive Parts: Aluminum castings, moldings, and other safety-critical components.

5.New Energy: Battery cell & module inspection for lithium-ion batteries.

6.Specialized Industries: Photovoltaic cells, molded plastics, ceramic substrates, and more.

Products Parameters

Machine Specifications :

| Item | Parameter | Item | Parameter | |

| Dimension: | 1500 × 1500 × 2100mm | Power Supply: | AC220V 10A | |

| Weight: | approx 1500KG | Packed weight: | Approx. 1800KG | |

| Package dimensions: | 1600 × 1600 × 2200mm | Power consumption: | 1.7KW | |

| Loading method: | manual | Detection mode: | offline | |

| Operation method: | manual | Permission management: | password |

X-ray tube:

| Item | Parameter | Item | Parameter |

| Light pipe type: | closed | Phototube current: | 200μA |

| Light tube voltage: | 90KV | Focus size: | 3-5um |

| Cooling method: | air cooling | Geometric magnification: | 300 times |

Imaging system:

| Item | Parameter | Item | Parameter |

| Detector: | New TFT | Radiation tolerance: | 10000Gy |

| Effective imaging area: | 130 × 130mm | Protection level: | IP65 |

| Pixel matrix: | 1536 × 1536 | Size: | 176 × 176 × 47mm |

| Pixel size: | 85μm | Weight: | 3.5KG |

| Spatial resolution: | 5.8lp/mm | Power: | 9W |

| Frame rate: | 20fps | Operative temperature: | 10-40℃ |

| AD conversion digits: | 16bit | Storage temperature: | -10-55℃ |

| Data interface: | Gigabit Ethernet | Operating humidity: | 20-90%HP (No condensation) |

| Trigger mode: | continuous acquisition, pulse synchronization | Storage humidity: | 10-90%HP (No condensation) |

| X-ray energy range: | 40KV-130KV | Image Settings: | Brightness, Contrast, Auto Gain and Exposure |

Industrial PC

| Item | Parameter | Item | Parameter |

| Monitor: | 21.5-inch high-definition monitor | Operating System: | Windows 10 64-bit |

| Operating instructions: | Keyboard/Mouse | Hard drive/Memory: | 1TB/8G |

Security guarantee

Radiation Dose:

Utilizes a steel-lead-steel protective structure, with the front door viewing window made of lead-containing glass for radiation shielding. At any position 20mm from the enclosure, the measured radiation dose equivalent rate ≤ 1 μSv/h, complying with international standards.

Lead Glass Viewing Window:

Transparent lead glass isolates radiation while allowing observation of the test object.

Safety Interlock:

All maintenance access doors are equipped with two high-sensitivity limit switches. Once any door is opened, the X-ray tube is immediately and automatically de-energized.

Electromagnetic Safety Door Switch:

The viewing window is fitted with an electromagnetic switch that prevents the window from being opened while the X-ray tube is in operation.

Emergency Stop Button:

Located next to the operator's position; pressing it immediately cuts off power.

Viewing Window:

Features a transparent viewing window, allowing direct observation of the sample during operation.

X-ray Tube Protection:

The X-ray tube must be shut down before leaving the software interface to perform other operations.

Detecting images

Choose our system not just as a PCB X-ray Machine, but as a complete Industrial X-ray Machine ecosystem designed to meet the rigorous demands of modern manufacturing and quality assurance, particularly for advanced ECU tester validation and beyond.