Pcb X Ray Inspection

Our high-performance X-Ray Inspection Machine is built for precision PCB X Ray Inspection and electronic component testing. With a maintenance-free sealed X-ray tube, 60° multi-angle tilt detection, and CNC automated inspection, it delivers fast, accurate results for manufacturers, testing labs, and electronics repair teams. Designed for ease of use, it features a 400×400mm stage, laser auto-positioning, and intuitive visual navigation to streamline your inspection workflows.

Description

Product Overview

Unmatched Performance: Our X-Ray Inspection Machine

Whether you need a xray pcb inspection machine for electronic manufacturing, a xray inspection machine for quality control labs, or a weld x ray inspection machine for industrial weld testing, our system is designed to exceed your expectations. Here's how it solves your pain points:

🔹 Durable, Low-Maintenance X-Ray Core

At the heart of our xray pcb inspection machine is a sealed X-ray tube (available in 90KV/110KV options) that offers an ultra-long lifespan and 100% maintenance-free operation. Unlike budget xray inspection machines that require frequent tube replacements, our system eliminates costly downtime and reduces long-term operational expenses-critical for high-volume production lines and weld testing facilities relying on a weld x ray inspection machine.

🔹 Next-Gen Imaging for Defect Detection

Our xray pcb inspection machine is equipped with a next-generation high-definition digital flat-panel detector, capturing crisp, high-resolution images in milliseconds. This rapid imaging capability lets you identify tiny defects (e.g., BGA voids, solder flaws, or weld cracks) without sacrificing speed, making it ideal for time-sensitive PCB testing and weld inspection tasks that demand a reliable weld x ray inspection machine.

🔹 Smart Positioning & Navigation

Laser Auto-Positioning: The integrated laser guide in our xray inspection machine lets you mark and lock inspection targets in seconds, eliminating manual alignment errors-whether you're testing a PCB with our xray pcb inspection machine or analyzing weld integrity with our weld x ray inspection machine.

Visual HD Navigation Window: The intuitive interface of our xray pcb inspection machine lets you quickly locate test points on the 400×400mm stage, cutting setup time by up to 30% for both electronic and weld inspection workflows.

🔹 Flexible, User-Friendly Operation

XYZ Axis Motion Control: Smooth, precise movement along all axes ensures full coverage of your workpiece, even for complex, multi-layer PCBs or large weld components. Our xray inspection machine adapts to your needs, whether you're using it as a xray pcb inspection machine or a weld x ray inspection machine.

60° Tilt Detection: Tilt the detector up to 60° to access side-angle defects (e.g., via solder penetration, component misalignment, or weld root cracks) that are invisible to standard top-down inspection. This feature sets our xray pcb inspection machine apart from basic xray inspection machines.

2-Hour Quick Training: The streamlined interface and intuitive controls mean your team can master our xray pcb inspection machine (or use it as a weld x ray inspection machine) in just 2 hours, with no specialized technical background required.

🔹 Automated CNC Inspection Mode

For high-throughput testing, our xray inspection machine features a CNC inspection mode that automates multi-point array scanning. Simply set your inspection parameters, and the system will auto-capture images, analyze defects, and generate reports-reducing human error and boosting efficiency by 40% for batch PCB testing or weld inspection with our weld x ray inspection machine.

Ideal Application Scenarios

Our xray pcb inspection machine / xray inspection machine / weld x ray inspection machine is perfect for:

1.PCB & Semiconductor Manufacturing: Inspecting BGA, CSP, and flip-chip components for voids, cold solder, and alignment issues.

2.Weld Quality Control: Detecting cracks, porosity, and incomplete fusion in automotive, aerospace, and industrial welds.

3.Electronics Repair Labs: Diagnosing hidden defects in mobile phone motherboards and industrial control boards.

4.LED & Battery Testing: Analyzing internal connections and structural integrity in sensitive electronic components.

Products Parameters

Overall Machine Status :

| Item | Parameter | Item | Parameter | |

| Dimension: | 1100 × 1200 × 2100mm | Power Supply: | AC220V 10A | |

| Weight: | approx 1400KG | Gross weight: | approx 1600KG | |

| Packed size: | 1300 × 1400 × 2200mm | Power: | 1.7KW | |

| Door opening: | manual | Detection mode: | offline | |

| Feeding method: | manual | Rights management: | password |

X-ray tube:

| Item | Parameter | Item | Parameter |

| Light pipe type: | closed | Phototube current: | 200μA |

| Light tube voltage: | 90KV | Focus size: | 5um |

| Cooling method: | air cooling | Geometric magnification: | 300 times |

Imaging system:

| Item | Parameter | Item | Parameter |

| Detector: | Amorphous silicon flat panel detector | Radiation tolerance: | 10000Gy |

| Effective imaging area: | 156×128mm | Protection level: | IP65 |

| Pixel matrix: | 1536 ×1536 | Size: | 196 ×162 ×37.5 mm |

| Pixel size: | 125µm | Weight: | 1.5KG |

| Spatial resolution: | 4.0lp/mm | Power: | 8W |

| Frame rate: | 30fps | Operative temperature: | 10-40℃ |

| AD conversion digits: | 16bit | Storage temperature: | -10-55℃ |

| Data interface: | Gigabit Ethernet | Operating humidity: | 20-90%HP (No condensation) |

| Trigger mode: | Continuous acquisition, pulse synchronization. | Storage humidity: | 10-90%HP (No condensation) |

| X-ray energy range: | 40KV-90KV | Image Settings: | Brightness, Contrast, Auto Gain and Exposure |

Industrial PC

| Item | Parameter | Item | Parameter |

| Monitor: | 21.5-inch high-definition monitor | Operating System: | Windows 10 64-bit |

| Operating instructions: | Keyboard/Mouse | Hard drive/Memory: | 1TB/8G |

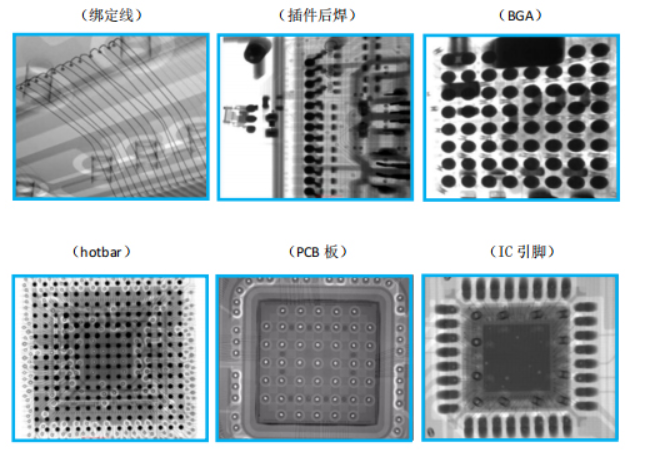

Detecting images