Best Price BGA Rework Machine

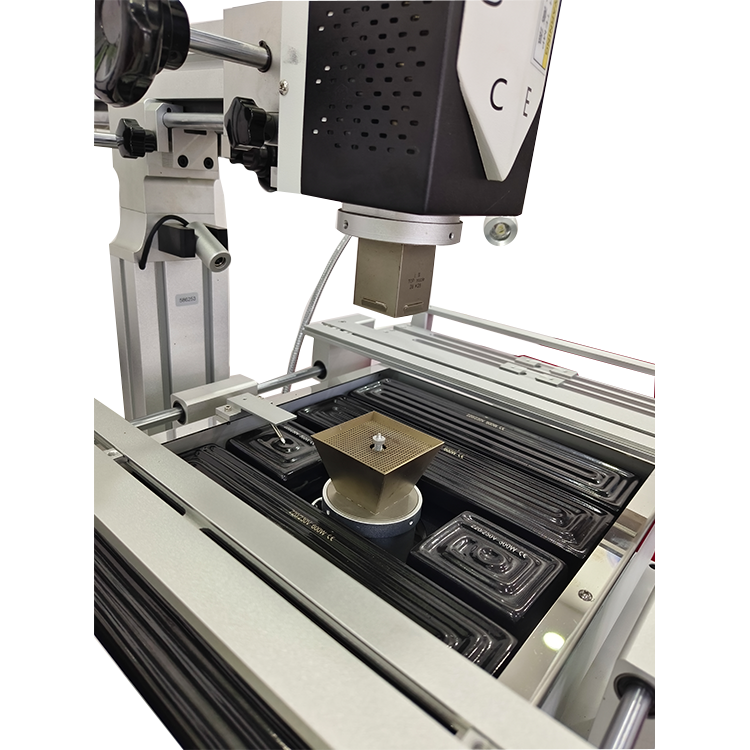

The Dinghua DH-5880 is a professional BGA rework machine designed for high-precision electronics servicing. As a reliable motherboard repair machine, it features a 3 zones heating BGA station with independent control of the upper hot air, lower hot air, and bottom infrared preheating zones, ensuring uniform heat distribution, preventing PCB warping, and delivering stable rework performance on high-density PCBs.

Description

Products Description

The Dinghua DH-5880 is a state-of-the-art BGA repair machine designed for high-precision electronics maintenance. As a professional-grade motherboard repair machine, it features an advanced 3 zones heating BGA station that allows for independent control of the upper hot air, lower hot air, and expansive bottom infrared (IR) preheating areas. This configuration ensures uniform thermal distribution, preventing board warping and ensuring successful reflow for even the most complex high-density PCBs.

Engineered for versatility, this BGA repair machine is widely used in the repair of laptops, game consoles, and automotive electronics. The motherboard repair machine utilizes a high-definition touch screen interface and laser positioning technology to achieve pinpoint accuracy during chip placement. With its high-power 3 zones heating BGA station, the DH-5880 provides the stability and thermal precision required to meet modern lead-free soldering standards, making it an essential tool for any professional rework facility.

Flexible and Reliable Repair Solution

Built with a combination of hot-air and infrared heating technology, the station features three independent heating zones-upper hot air, lower hot air, and an infrared preheating zone-to deliver uniform temperature distribution and minimize thermal stress on PCBs. This ensures secure and efficient reflow soldering for even delicate assemblies.

Intelligent Temperature Control

Equipped with real-time monitoring and external temperature sensors, the system displays both set and actual temperature profiles, allowing operators to analyze and adjust parameters with precision. The closed-loop K-type control provides stable heat regulation with minimal deviation.

Products specification

| 1 | Item | Parameter |

| 2 |

Total Power |

5600W |

| 3 |

Top heater |

1200W |

| 4 |

Bottom heater |

the second temperature zone 1200W,infrared temperature zone 3000W |

| 5 |

power |

AC220V±10% 50Hz |

| 6 |

Dimensions |

L630×W730×H680 mm |

| 7 |

Positioning |

V-groove + universal fixture + 5-points support + Adjustable in X direction |

| 8 |

Temperature control |

K Sensor, closed loop |

| 9 |

Temp accuracy |

±2℃ |

| 10 |

PCB size |

Max 440×360 mm Min 22×22 mm |

| 11 |

BGA chip |

2X2-80X80mm |

| 12 |

Minimum chip spacing |

0.15mm |

| 13 |

External Temperature Sensor |

4(optional) |

| 14 |

Net weight |

48kg |

Products key features

Convenient and Safe Operation

Vacuum suction pen for safe and convenient chip pick-up after desoldering.

USB 2.0 interface for connection to a computer or mouse, enabling screenshot capture and future system upgrades.

High-power cross-flow cooling fan prevents PCB warpage and protects nearby components.

Intelligent audio reminder alerts operators before heating completion.

Comprehensive safety protection with overheat guard for secure use.

These thoughtful features make the station easy to operate while enhancing rework success rates and reliability.

Ideal for Mobile Repair and Electronics Maintenance

Compact and cost-effective, this manual BGA rework station is especially popular in the mobile phone repair field, as well as laptop, gaming console, and general PCB maintenance work. Its space-saving footprint and professional-grade performance make it ideal for both small repair shops and large service centers.

certification

our company