BGA Hot Air Rework Station

BGA hot air rework station is an equipment used to remove and replace the ball grid array components on printed circuit boards(PCBs). One of its key features is the large infrared preheating zone, which uniforms heat distribution and reduces the risk of PCB deformation. It supports PCB size up to 650*600 mm, making it suitable for large and complex motherboards. Also the station equipped with an optical alignment CCD camera that provides precise visual positioning of solder balls and components, ensuring high acuracy rework resluts.

Description

Products Description

Dinghua DH-A5 is a BGA hot air rework station used to remove and replace the ball grid array(BGA) components on printed circuit boards(PCBs).

One of its key features is the large infrared preheating zone, which uniforms heat distribution and reduces the risk of PCB deformation. It supports PCB size up to 650*600 mm, making it suitable for large and complex motherboards.

Also the station equipped with an optical alignment CCD camera that provides precise visual positioning of solder balls and components, ensuring high acuracy rework resluts. This equopment is ideal for requiring high precision and reliability PCB repair and assembly.

This BGA rework station features three indepenent temperature zones(top hot air heater, bottom hot air heater, and infrared reheating zone).

The HD touch screen provides real-time temperature dispaly, allowing engineers adjust parameters to match the specific melting point of different components.

Since various chips require different temperature curves, the system supports up to 50000 groups stored temperature profiles. The optical alignment system ensures accurate positioning, making the removal and replacement of BGA components significantly more efficient and reliable.

Additionally, the machine is equipped with vaccum pickup mechanism, it will pick the chip up automatically after desoldering, improving safety and workflow efficiency.

Products Specification

|

Item

|

Parameter

|

|

Power supply

|

AC220V±10% 50/60Hz

|

|

Total power

|

9200w

|

|

Top heater

|

1200w

|

|

Bottom heater

|

1200w

|

|

IR Preheating Area

|

6400w

|

|

Operation mode

|

Fully automatically disassemble, suction, mounting and soldering

|

|

Chip feeding system

|

Automatic receiving, feeding, automatic induction (optional)

|

|

Temperature profile storage

|

50000 groups

|

|

Optical CCD lens

|

Automatic stretch out and go back

|

|

PCBA positioning

|

Up and down intelligent positioning,bottom "5-point support" with V-groove fixed PCB which can be adjusted freely in the X-axis

direction, with universal fixtures meanwhile

|

|

BGA position

|

Laser position

|

|

Temperature control

|

K-type Sensor,Closed loop and 8~20 segments for temperature controlling program

|

|

Temperature accuracy

|

±1 ℃

|

|

Positon accuracy

|

0.01mm

|

|

PCB size

|

Max 640*560 mm Min 10*10 mm

|

|

PCB thickness

|

0.2-15mm

|

|

BGA chip

|

1*1-100*100mm

|

|

Minimum chip spacing

|

0.15mm

|

|

External Temperature Sensor

|

5 pcs(optional)

|

Detail Pictures

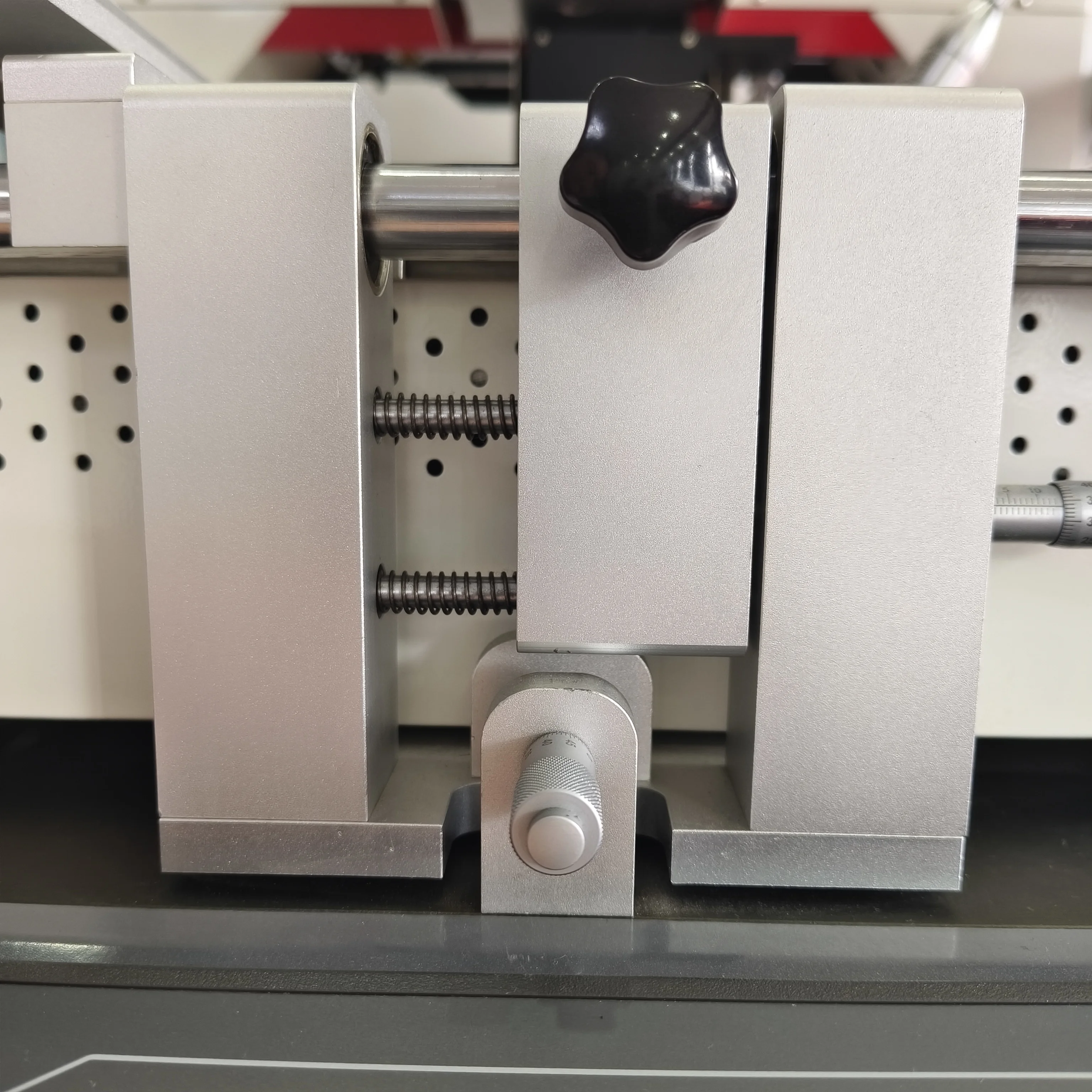

Micrometer alignment adjust

The micrometer could precisely adjust the position of motherboard and the chips, making the BGA ball and BGA soldering position completely conincide and improving the accuray and efficiency of optical alignment.

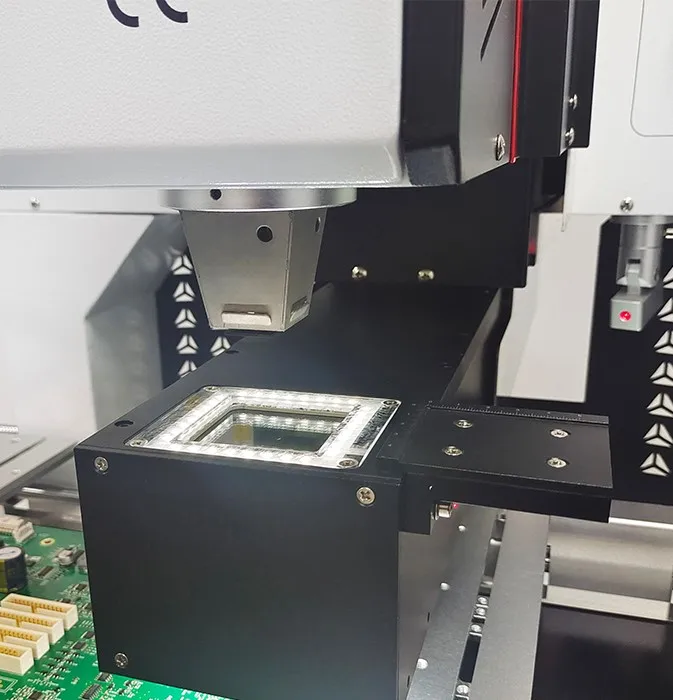

Optical Alignment CCD Camera

The optical alignment CCD camera system has been developed to ensure very accurate placement during BGA chip removal and placement. With high resolution imaging and real time display, the CCD camera is capable of capturing the PCB pad and the solder balls at the same time, allowing the operator to obtain accurate placement alignment through image overlay.

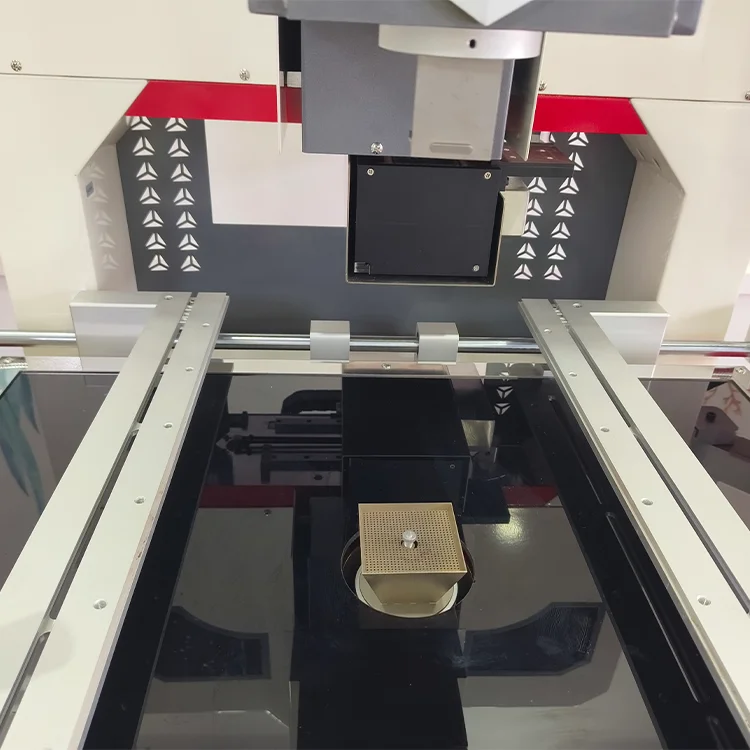

Infrared Preheating Zone

The bottom infrared heating areas are all controlled by switch, and you can choose the bottom heating areas depend on the PCB board size. The size of infrared preheating zone is about 650*600mm. Large infrared preheating zone could uniform heat distribution.

Vacuum Pick-up system

The vacuum pick-up system is designed for safely and effectively lifting components during the rework process. It will automatically pick up the chip once the solder has completely melted, resulting in smooth and damage-free removal. The system features stable suction control and is equipped with protective pressure-sensing functions, designed to avoid excessive PCB force.

Products Structures

The DH-A5 BGA Rework Station is a semi-automatic solution for repairing laptop, mobile phone, Xbox, PlayStation, and other PCB (Printed Circuit Board) motherboards with precision. Utilizing infrared preheating and hot-air convection, it provides stable and uniform heat for soldering and desoldering processes.

Furthermore, this equipment is capable of simulating the temperature curve of a reflow soldering process making reliable removal and replacement of BGA and other high-density components possible with ease. Due to this versatility, the DH-A5 can be found in electronics manufacturing, repair centres, research institutions, and colleges of technology.

Company profile

About our company

Our company is a national high-tech enterprise. Our products: BGA rework stations, Xray inspection machine, automatic soldering machines, SMT related equipment.

Our products enjoy global recognition, being exported to over 80 countries and regions. Dinghua has established a robust sales network and terminal services system, making them a pioneer and guide in the SMT soldering industry.

Our products find applications in diverse sectors like individual maintenance, industrial and mining enterprises, teaching and research, and aerospace, earning a good reputation among users. Believing that clients' successes is our own, Dinghua strives to work together to build a better future.