BGA Rework Station With Optical Alignment

Dinghua DH-A2E is a BGA rework station with optical alignment used in high precision PCB repair.It has three independent temperature zones,optical alignment CCD camera,vaccum sucker,HD touch screen,real-time temperature profile display and etc.It provides engineers with precise alignment, stable heating, programmable temperature control, and a user-friendly interface-thus providing a high success rate repairing complex integrated circuits, and safety for the PCB.

Description

Products Description

Dinghua DH-A2E is a BGA rework station with optical alignment provides a reliable solution for professionals handling complex SMD and BGA components found in smartphones, laptops, communication modules, and various industrial control boards.

At the core of the DH-A2E is its advanced hot-air heating system combined with infrared bottom heating. This three independent temperature zones design delivers stable and uniform temperature distribution across the board to reduce thermal stress and prevent PCB deformation. The station can also control temperature profiles accurately, the station ensures safe, consistent reflow for components such as BGA, QFN, SOP, CSP, and other fine-pitch devices.

The DH-A2E features an optical alignment system that enables precise chip placement before soldering. The high-resolution camera and adjustable imaging platform allow operators to align solder balls and PCB pads accurately, reducing the risk of misalignment, and rework failure.

Designed for both experienced technicians and beginners, the station integrates an intuitive control interface with program-based temperature management. Operators can store, edit, and temperature profiles. Operators can also use automatic lifting devices, real-time temperature profile dispaly and three independent temperature zones to increase user-friendliness and operator safety.

Products Specification

|

Item

|

Parameter

|

|

Power Supply

|

AC220V±10% 50/60Hz

|

|

Total Power

|

4900w

|

|

Top Power

|

1200w

|

|

Bottom Power

|

1200w

|

|

Infared Power

|

2400w

|

|

Dimension

|

77*81*102mm

|

|

Operation Mode

|

Automatic + Manual

|

|

Temperature Profile Storage

|

10000 groups

|

|

Temperature Control

|

K Sensor + Closed Loop

|

|

Temperature Accuracy

|

±1℃

|

|

Position Accuracy

|

±0.01mm

|

|

PCB Size

|

Max 400×450 mm Min 10×10 mm

|

|

BGA Chip

|

2*2-80*80mm

|

|

External Temperature Sensor

|

1 pcs(optional)

|

|

Net weight

|

70kg

|

|

Machine type

|

Desktop

|

|

Minimum chip spacing

|

0.1mm

|

|

Camera pixel

|

6 millions

|

|

Chip feeding

|

automatically take or put

|

|

PCBA Positioning

|

Up and down intelligent positioning, the bottom "5 point support"with v-type card slot fixing PCBA which can be freely adjusted in

X-axis direction, with external universal fixtures

|

|

BGA position

|

Laser positioning v-shaped card slot and universal fixtures

|

|

Optical CCD Lens

|

Automatically going out , back and focus

|

Products Details

HD Touch Screen

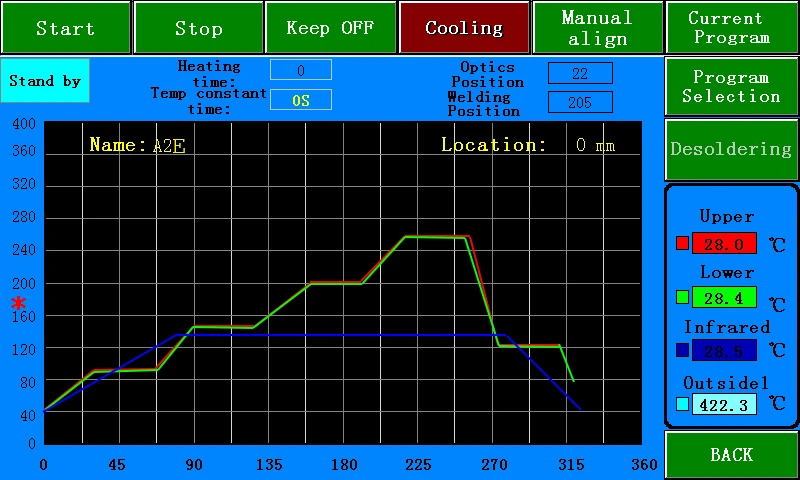

This machine offers three modes-soldering, desoldering and position. Operators can select the most appropriate mode for each rework task. It provides real-time temperature monitoring for the top heater, bottom heater and the infrared heating zone, ensuring precise control throughout the process. Operators can store, edit, replicate the temperature value of the temperature profile. Essential function such as start, stop, and cooling are fully controllable for safe and efficient operation. This machine equipped with optical alignment system, but it also supports manual alignment. Giving the technician the flexibility to adjust the position of components.

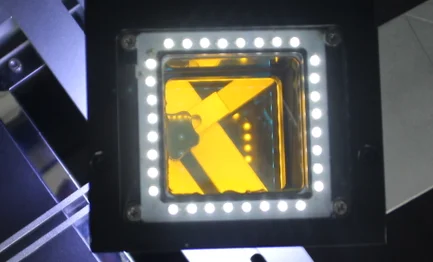

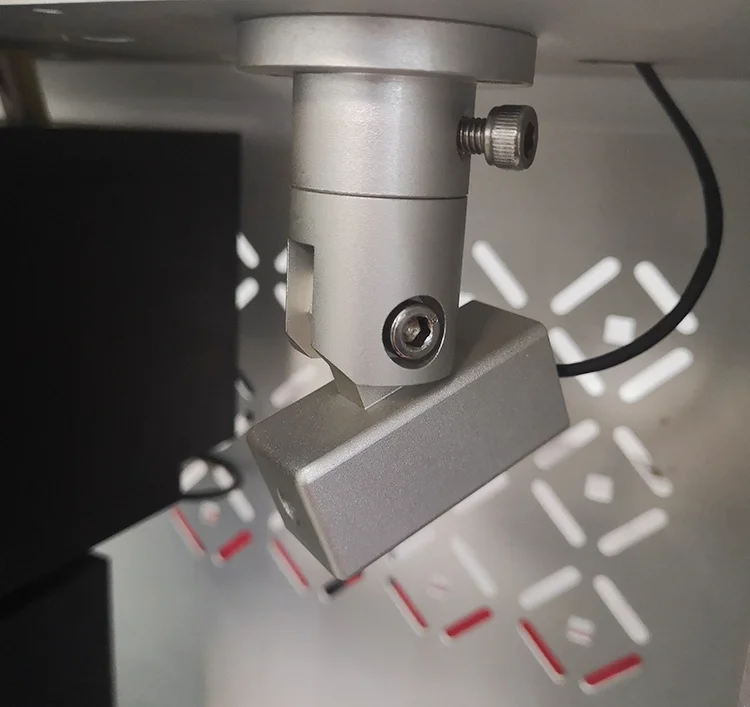

Optical Alignment CCD Camera

CCD high-definition digital camera, automatic optical zoom, laser positioning. The CCD camera lens is foldable automatic extension and retraction.

The image will displaying on monitor screen and can be zoom in and zoom out for precision alignment.

Joystick

The joystick allows precise control of the camera's position, enabling smooth vertical (up and down) adjustments. It also manages the zoom in and zoom out functions for the CCD camera, allowing operators to easily optimize the image displayed on the monitor.

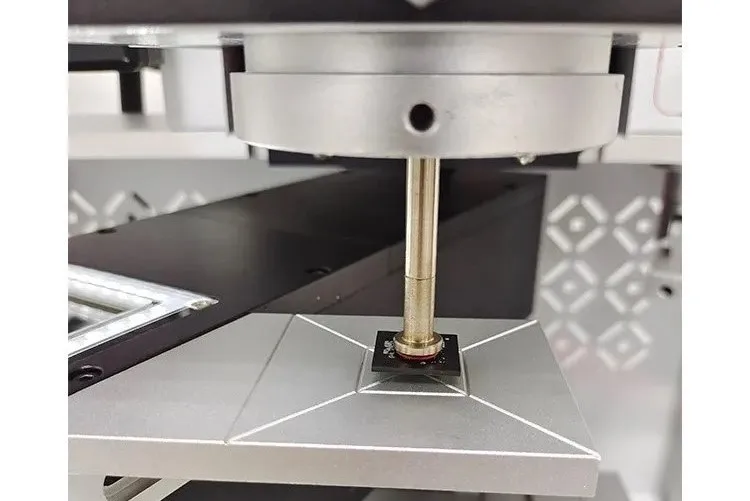

Vaccum Pickup System

The vacuum pickup system automatically lifts the chip after desoldering. Equipped with a pressure-sensing safety device to prevent excessive downward force, effectively protecting the PCB from damage.

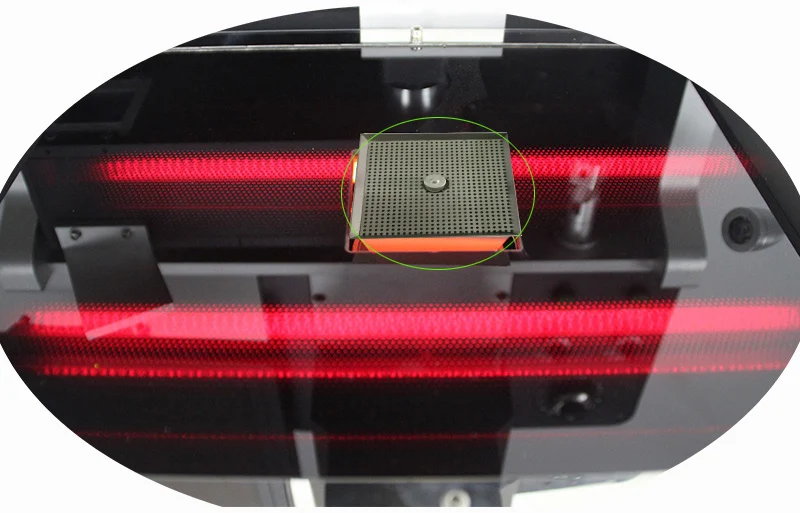

Infrared Preheating Zone

The infrared preheating zone ensures uniform heat distribution, effectively reducing thermal stress and providing better protection for the motherboard.

Laser Pointer

The laser pointer assists in accurately positioning the PCB motherboard, ensuring precise alignment during the rework process.

Company Profile