LGA Rework

1. LGA is Land Grid Array which is a type of pakage technology; 2. No need desolder its small PCBa in LGA; 3. Whole LGA will be automatically removed using special jig; 4. Better protect LGA from heating up.

Description

Fully automatic LGA rework machine with professional jig and nozzles

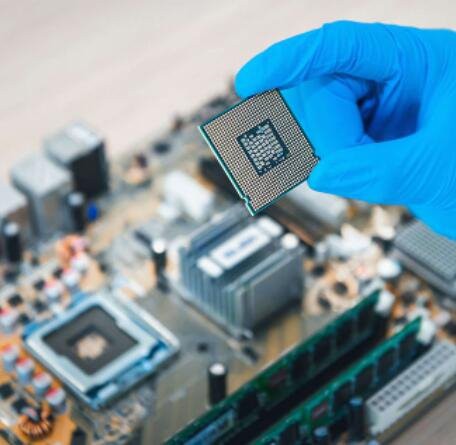

(Land Grid Array) A chip package with a very high density of contacts. LGAs differ from traditional chips with protruding pins that are inserted into a socket. An LGA chip has flat pads on the bottom of its package that touch contacts on the motherboard socket.

In view of LGA special structure, and quick rework & high effiency to repair, we provide customized service for different LGA chips repairing.

Removing LGA chip

Basic information

|

Model |

DH-A2E |

|

Power supply |

110~220V +/- 10% 50/60Hz |

|

Rated power |

5000W |

|

Upper heating |

Hot-air which can be adjsuted |

|

Bottome heating |

hybrid heating for PCBa and chip-level |

|

Mounting |

Optical alignment, visible procedures, accuracy 0.01mm |

|

PCB size |

10*10~450*500mm |

|

Chips available |

1*1~80*80(more than 80*80mm, optional) |

|

Automation level |

High-automatic |

|

LGA mounting |

Automatically pick up and replace to motheboard |

|

Soldering ball |

Lead or lead free and solder paste( user providing) |

|

Power plug |

As customer's requirement |

|

Frequency |

3 hours working, 10 minutes rest |

|

Chip-feeder |

Automatically carry a chip to solder or receive and go back |

|

Nozzles Jigs |

Customize 20*20~100*120mm (optional) Customized for different LGA picked up or replaced |

|

Dimension |

600*700*850mm |

|

Weight |

70kg |

Procedures to LGA rework

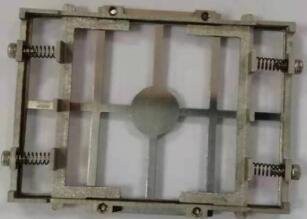

1. preparing a jig as below:

Customizing a jig as per LGA structrue, width,length and height etc. which can

make sure whole LGA can be picked up and don't damage chip inner components.

2. Removing/desoldering

After desoldering LGA, whole LGA hold by a jig automatically was put on

that machine's chip-feeder waiting for cleaning.

Chip-feeder and optical CCD camera working together, always automatically

open and close.

3. Using a renewed chip or just a fully new chip insead.

You can avoid weeks of delays and a comparably significant sum of money by using LGA rework. When a delay seems unavoidable, a well-executed rework will allow you to meet your customer's deadlines. DH(Dinghua) has successfully completed experience for a significant number of clients, ranging from major enterprises, for instance, Google, Teleplan, Huawei and Foxconn etc., to small shops, such as, personal repairing shop, appointed after-sales service sitesand so on , many of whom had complicated documentation needed for assurance in reliability-critical industries.

4. Visible optical CCD aligning process

After aligning(chip will be totally put in its right position on a motherboard), the chip will be automatically carried to solder.

5. Automatically Solder

Automatically mount to its motherboard, automatically heat up using hot-air and infrared heating, even automatically cool after work finishing.

Why use DH(Dinghua) for LGA rework?

Advanced soldering techniques and highly qualified machine are manufactured,and consistent, repeatable, and above all dependable LGA rework, which frequ-ently necessitates the creation of unique jig and stencils, board solder masking,

and frequently even the bonding of new pads to the PCB. After the rework is fin-shed, the board is examined using endoscopes and X-rays to ensure the rewo-rk's reliability and integrity. Companies rely on DH(Dinghua) to execute this

ser-vice because of our skill and attention to detail when harvesting LGAs from circ-uit boards when components are not readily available.

DH(Dinghua)has in-depth experience developing solutions for reliably reworking LGAs

and other equipment, such as, X-ray inspector machine and X-ray counting machine etc.