Laser Positioning BGA Welding Tools

1.hot air nozzles 2.k sensor close loop control 3.v-groove pcb support 4.hd color optical alignment system

Description

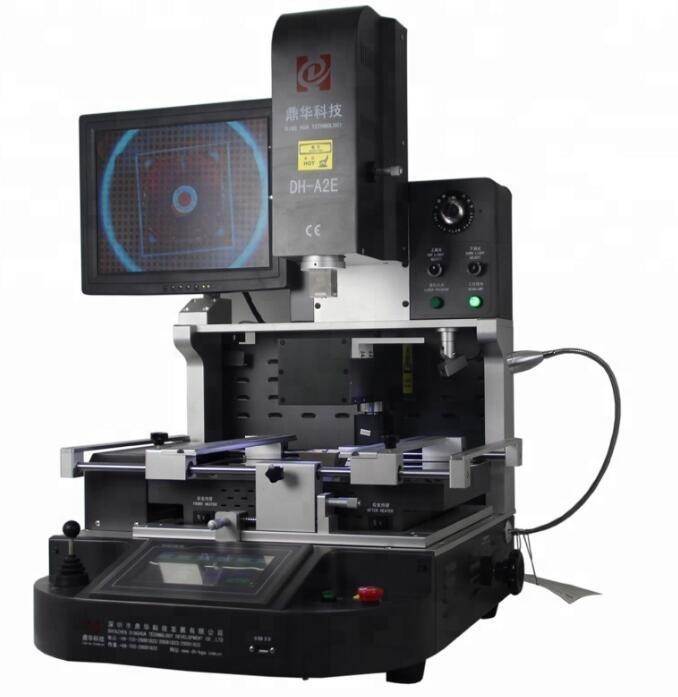

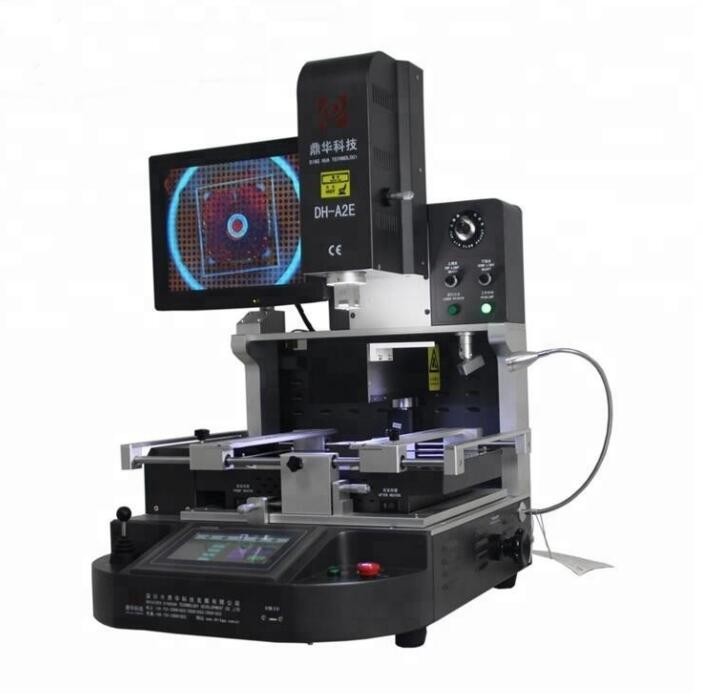

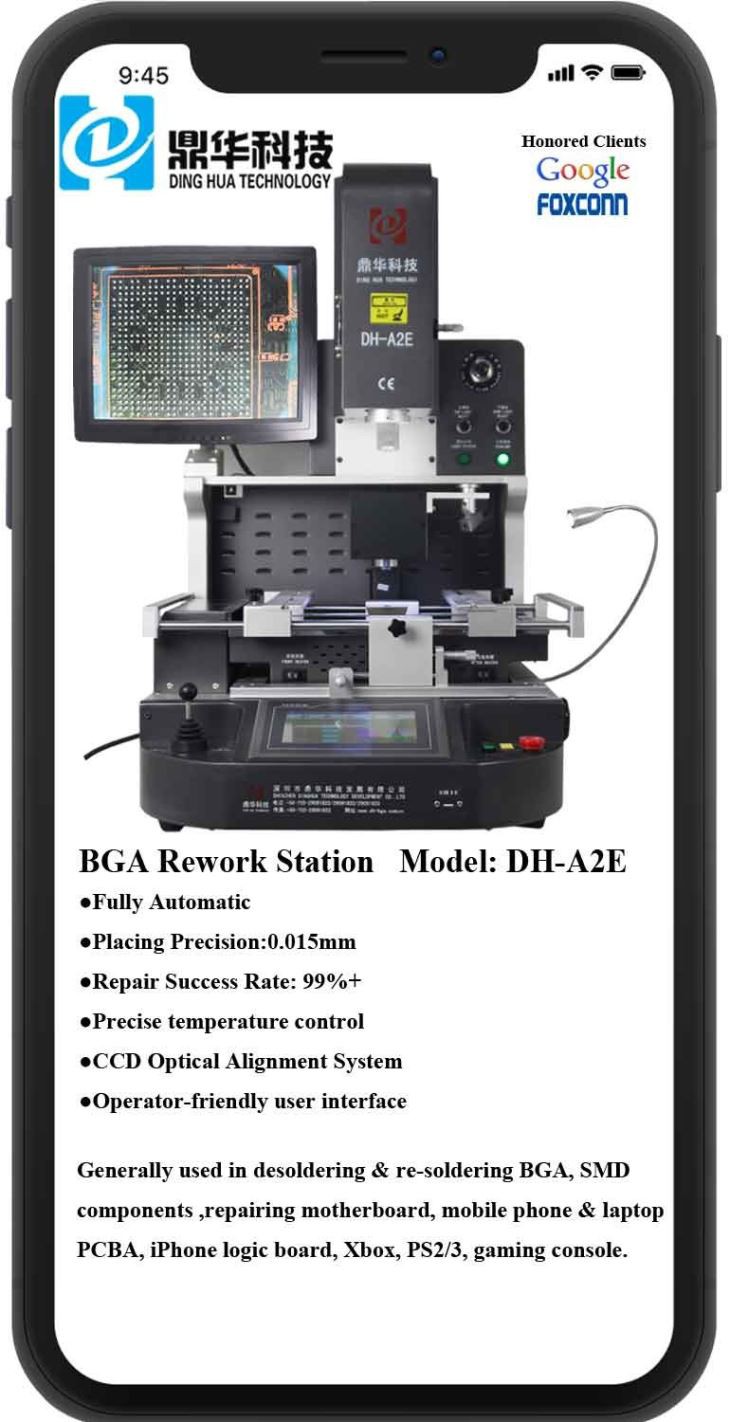

Laser Positioning BGA Welding Tools DH-A2E

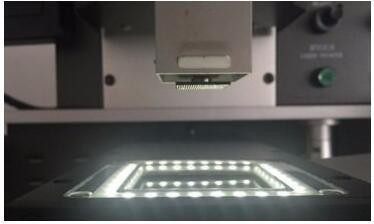

Working Demo:

Laser Positioning BGA Welding Tools are essential in the electronics industry for precise placement, alignment, and soldering of BGA components on PCBs. They use laser technology to ensure accurate positioning and are integrated with rework stations for controlled heating and soldering. Key features include laser alignment systems, non-contact sensors, and closed-loop temperature control, which together enhance precision and efficiency. These tools are ideal for high-precision electronics repair, prototyping, and small-scale manufacturing, offering versatility and reliability in handling various BGA components in advanced electronic devices.

Desoldering BGA Ball and tin

Specifications:

| 1 | Total power | 5200w |

| 2 | 3 independent heaters | Top hot air 1200w, lower hot air 1200w, bottom infrared preheating 2700w |

| 3 | Voltage | AC220V±10% 50/60Hz |

| 4 | Electric parts | 7'' touch screen + high precision intelligent temp control module + stepper motor driver + PLC + LCD display + high resolution optical CCD system + laser positioning |

| 5 | Temperature control | K-Sensor closed-loop + PID automatic temp compensation + temp module, temp accuracy within ±2℃. |

| 6 | PCB positioning | V-groove + universal fixture + movable PCB shelf |

| 7 | Applicable PCB size | Max 370x410mm Min 22x22mm |

| 8 | Applicable BGA size | 2x2mm~80x80mm |

| 9 | Dimensions | 600x700x850mm (L*W*H) |

| 10 | Net weight | 70 Kg |

Applications:

Characteristic:

Laser Positioning BGA Welding Tools DH-A2E

The DH-A2E is the most advanced BGA rework system available on the market today. It can easily install and remove BGA, QFN, µBGA/CSP, Flip Chip, and other SMDs. Featuring a 1200W hot air top heater and a 2700W IR bottom preheater, it saves you thousands in additional costs. It uses a unique infrared heating system to control and precisely apply heat, protecting adjacent components. Using a high-quality, specially developed IR thermal sensor, the process is completely closed-loop temperature controlled, using non-contact measuring methods.

Packing List :

Materials: Strong wooden case+wooden bars+proof pearl cottons with film

1pc brush pen

1pc Instruction Manual

1pc CD video

3pcs top nozzles

2pcs bottom nozzles

6pcs universal fixtures

6pcs fastened screws

4pcs support screw

Sucker size: Diameters in 2,4,8,10,11mm

Inner hexagon spanner: M2/3/4

Dimension:81*76*85CM

Gross weight: 115 kg

Flexible delivery

•TNT

•DHL

•FedEx

•UPS

•EMS

•BY SEA