Touch Screen Video BGA Rework Station

Touch screen video bga rework station Quick preview: Promotional price! DH-A1L BGA Rework Machine, equipped with HD touch screen is now in stock. We devoted ourselves to bga rework & automatic machinery,covering most of India, Europe and the American market.We are expecting become your long...

Description

Touch screen video bga rework station

Quick preview:

Promotional price! DH-A1L BGA Rework Machine, equipped with HD touch screen is now in stock. We devoted ourselves to bga rework

& automatic machinery,covering most of India, Europe and the American market.We are expecting become your long time partner in China.

1. Specification

|

|

||||||||||||||||||||||||||||||||||||||||

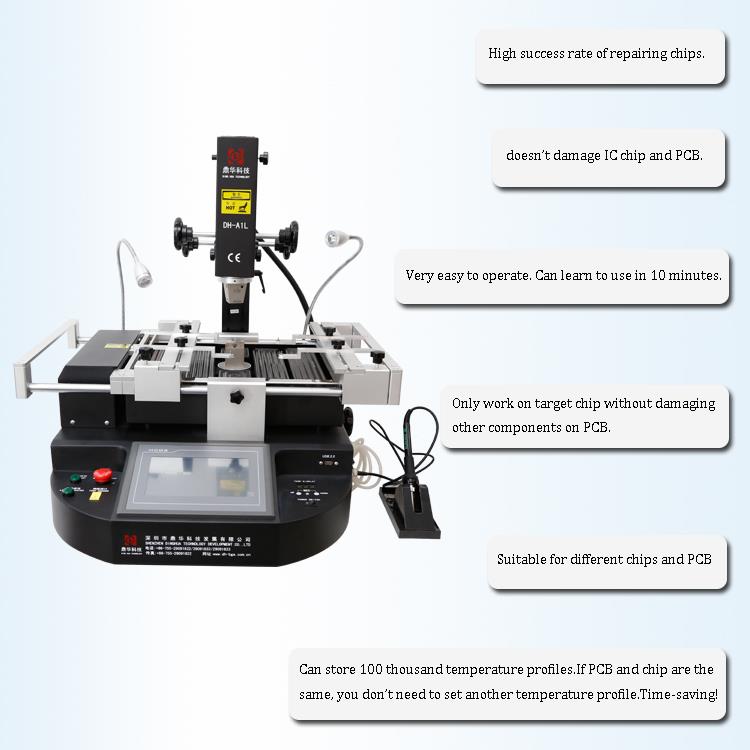

2.Main features of the DH-A1L BGA rework station

Key Specifications/Special Features:

This machine has the strong and perfect function selection, with eight temperature waves in the memory software,you can select the right temperature wave according to the solder/unsolder request.

Intelligent temperature wave heating, can achieve the soldering /desoldering

adjustable lamp body, use laser light, suitable for desoldering any-angle components.

PID intelligent temperature control can avoid the IC damage due to the fast or uninterrupted warming up.

This machine has a super hot melt system, use infrared welding technology which is developed independently, heat is easy to pierce and distribute evenly, can suit for a variety

of computer, notebook, play station's BGA components, especially suits to the computer north and south bridge.

Friendly human-machine operation interface, perfect LCD display, you can watch the whole repairing process very clearly.

Ergonomic design, practical and easily operated. Good build quality but at the same time light weight and a small footprint allows the T-890 to be easily bench positioned,

transported or stored.

3.Why you should choose DH-A1L BGA rework station?

4. Related Knowledge:

4.1HIGH-RELIABILITY COMPONENT INSTALLATION

The particular Process Goals and Guidelines for safe, high-reliability component installation are as follows:

Surface Mount Components

-Prefill lands or apply solder paste

-Align and place component to lands (tack if necessary)

-Apply solder paste to lead/land area if not applied prior to component placement

-Pre-/auxiliary heat assembly and/or component if required

-Pre-dry applied solder paste

Solutions and systems for soldering, rework and repair of electronics

4.2Hand Soldering Manual for Rework / Repair & Assembly

General

-Reflow solder joints (individually, in groups or all together) with concentrated "targeted" heat in a rapid, controllable manner

while maintaining lead/land alignment. Joints should remain at target temperature (above melting point of solder alloy) for

proper time to achieve optimal intermetallic formation.

-Avoid thermal and/or mechanical damage to component, board, adjacent components and their joints.

-Clean and inspect

4.3Thru-hole Components

-Insert new component into board

-Pre-/auxiliary heat assembly and/or component if required

-Solder joints (individually, in groups or all together) with concentrated "targeted" heat in a rapid,

controllable manner. Joints should remain at target temperature (above melting point of solder al-loy) for proper time to achieve

optimal intermetallic formation.

-Avoid thermal and/or mechanical damage to component, board, adjacent components and their joints

-Clean and inspect

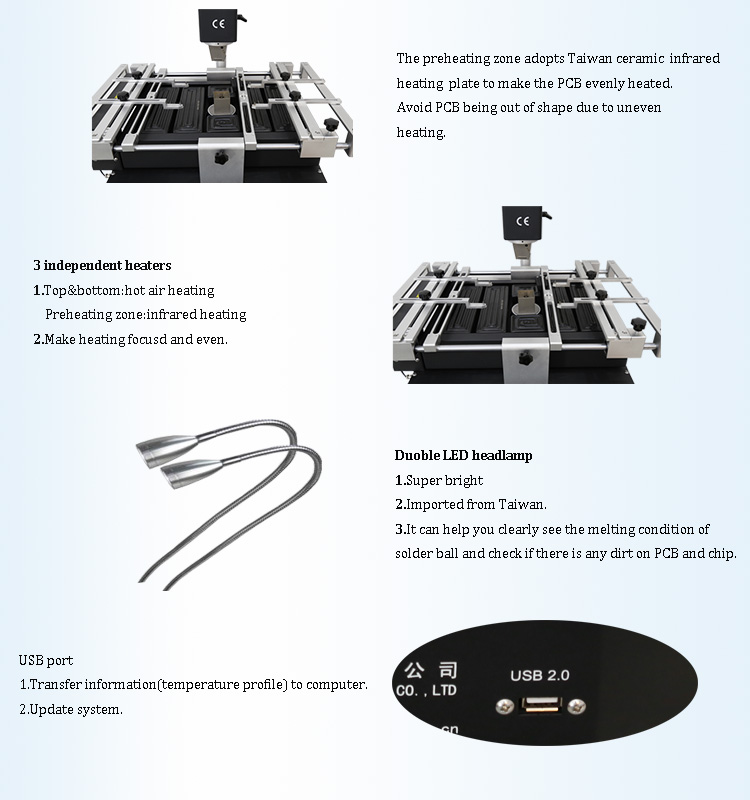

5.Detailed Images of DH-A1L BGA REWORK STATION

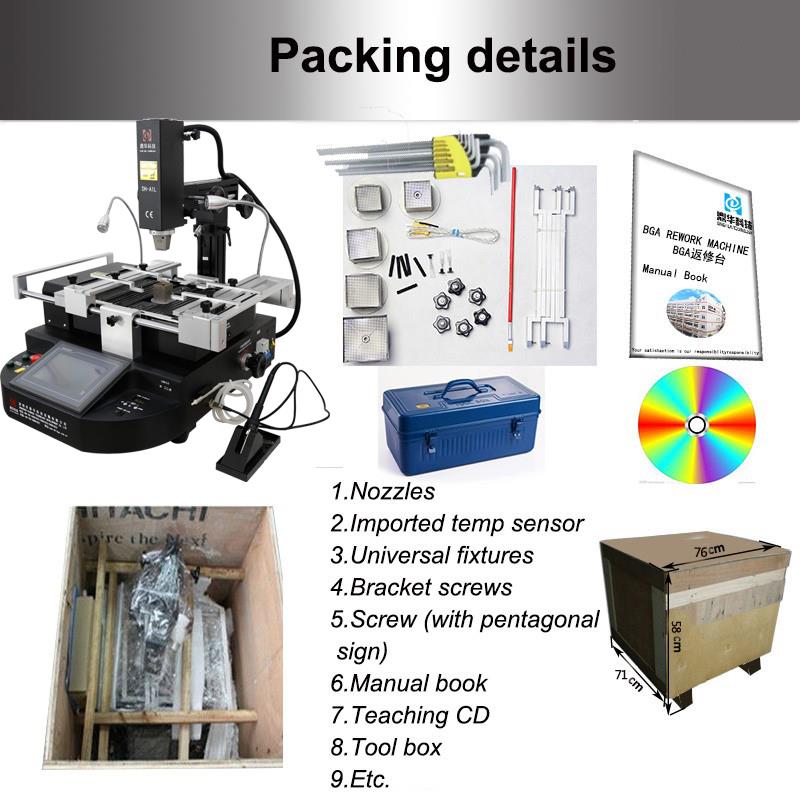

6. Packing & delivery details of DH-A1L BGA REWORK STATION

Packing List:

Machine:1 set

All packed in stable and strong wooden cases,suitable for import and export.

Top nozzle:3 pcs (31*31mm,38*38mm,41*41mm) /Bottom nozzle:2pcs(34*34mm,55*55mm)

Beam:2 pcs

Plum knob: 6 pcs

Universal fixture:6 pcs

Support screw:5 pcs

Brush pen:1 pcs

Vacuum cup:3 pcs

Vacuum needle:1 pcs

Tweezer:1 pcs

Temp sensor wire:4 pcs

Professional Instruction Book:1 pcs

Teaching CD: 1 PCS

Delivery detials of DH-A1L BGA REWORK STATION

We will use FedEx/DHL/UPS/TNT/EMS for fast and safe shipping. We will use the most convenient one when you

buy the product.

· Before shipping, we will pack every product well for you. And please check the outside package when you receive

the parcel well

· If you have special requirement for shipping, please let us know in advance.

|

Shipping: |

|

1.Shipment will be done within 5 business days after receiving payment. |

|

2.Fast delivery shipment by DHL,FedEX,TNT ,UPS and other ways including by sea or by air. |