X Ray Machine For Pcb

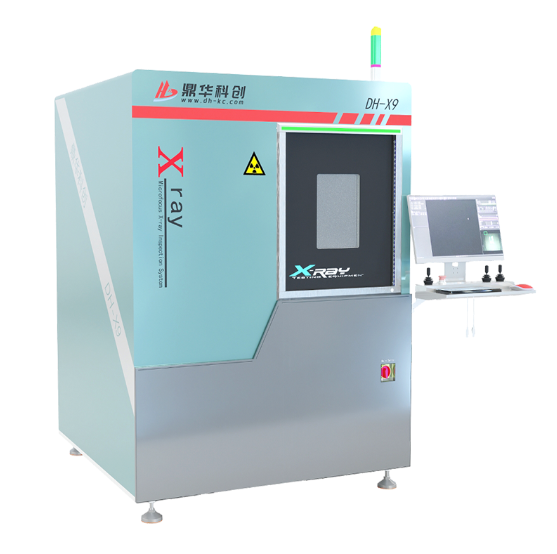

X-ray non-destructive testing instrument, 3D CT planar direct scanning DH-X9

Description

Products Introduction

1.The stage can move along the X and Y directions, providing a larger effective inspection range, improving product magnification and inspection efficiency. The stage is also capable of 360° rotation. (industrial x ray inspection equipment)

2.The image detector can tilt up to 60°, allowing easy observation of side defects in products, such as BGA virtual soldering and through-hole solder leakage.(x ray inspection system factory)

3.The X-ray source uses a sealed tube with a long service life and requires no maintenance.

4.X-ray reception is handled by a high-definition digital flat-panel detector.(pcb x ray machine)

5.A visual automatic navigation window makes operation convenient and enables quick location of inspection target positions.

6.The stage platform offers an ultra-large inspection space with a diameter of 530mm (suitable for oversized industrial motherboards, LED light strips, etc.).

7.Editable inspection programs support large-volume automatic inspections, improving efficiency and automatically identifying defective products.

8.Rework digital library management allows for saving edited inspection programs and inspection result images.

9.MWS/ERP system integration can be customized for convenient management.

Products Parameters

industrial x ray inspection equipment:

Machine Status:

| Item | Specification | Item | Specification |

|---|---|---|---|

| Dimensions | 1475×1465×1930mm | Power Supply Voltage | AC220V 10A |

| Weight | Approx. 2100KG | Packed Weight | Approx. 2500KG |

| Packed Dimensions | 1650×1650×2200mm | Power | 1.9KW |

| Door Opening Method | Manual | Inspection Mode | Offline |

| Loading Method | Manual | Access Control | Password |

X-ray Tube:

| Item | Specification | Item | Specification |

|---|---|---|---|

| Tube Type | Closed-type | Tube Current | 200μA |

| Tube Voltage | 90KV-130KV | Focal Spot Size | 5μm |

| Cooling Method | Air-cooled | Geometric Magnification | 300x |

Imaging System:

| Item | Specification | Item | Specification |

|---|---|---|---|

| Detector | New-type TFT | Radiation Tolerance | 10000Gy |

| Effective Imaging Area | 130×130mm | Protection Class | IP65 |

| Pixel Matrix | 1536×1536 | Dimensions | 176×176×47mm |

| Pixel Size | 85μm | Weight | 3.5KG |

| Spatial Resolution | 5.8lp/mm | Power Consumption | 9W |

| Frame Rate | 20fps | Operating Temperature | 10-40°C |

| AD Conversion Bits | 16bit | Storage Temperature | -10-55°C |

| Data Interface | Gigabit Ethernet | Operating Humidity | 20-90%RH (non-condensing) |

| Trigger Mode | Continuous Acquisition, Pulse Synchronization | Storage Humidity | 10-90%RH (non-condensing) |

| X-ray Energy Range | 40KV-90KV | Image Settings | Brightness, Contrast, Auto Gain & Exposure |

Industrial Control Computer:

| Item | Specification | Item | Specification |

|---|---|---|---|

| Monitor | 21.5-inch HD Monitor | Operating System | Windows 10 64-bit |

| Operation Method | Keyboard/Mouse | Hard Drive/RAM | 1TB/8G |

Example images

Our Company

Shenzhen Dinghua Technology Co., Ltd. is a national high-tech enterprise integrating the R&D, production, sales and service of X-ray counting machines, X-ray NDT machines, BGA rework stations, and automation equipment! We have the absolute strength to provide you with high-quality products, perfect services and advanced technical support.

Found in 2011, Dinghua Technology has been focusing on the R&D and production of X-RAY counting machines, X-ray NDT machines, BGA rework stations, and automated production equipment. The company takes "research and development as the foundation, quality as the core, and service as the guarantee" and is committed to creating "professional equipment, professional quality, and professional service"! At the same time, the company adheres to the development concept of "professionalism, integrity, innovation, and pragmatism" and has established a professional technical research and development team. It constantly absorbs and draws on domestic and foreign industry development experience, boldly explores, introduces new ideas, and realizes the transformation from traditional hardware combination to integration. The second revolution in the control industry, becoming a pioneer and leader in X-ray counting or NDT, BGA rework stations, and automation production equipment industries.

Company Honor Certificate