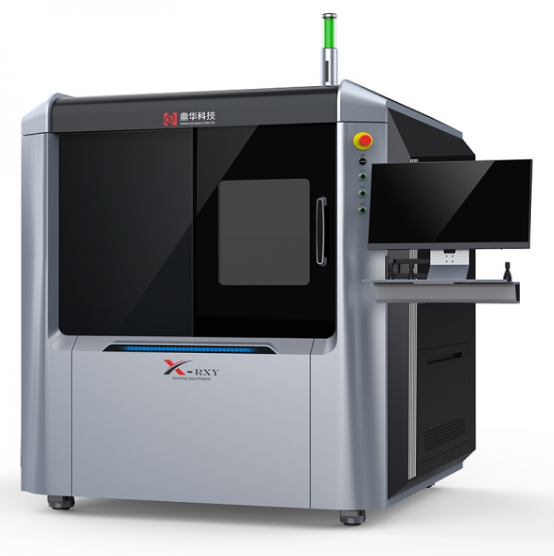

Xray Inspection Machine

The Dinghua X-Ray Non-Destructive Testing Instrument DH-X8 features a closed X-ray tube, a high-definition digital flat panel detector, laser automatic navigation and positioning, and CNC detection mode with X/Y/Z axis motion control. It also includes a 360-degree rotation function for multi-angle inspection, offering simple and fast operation to quickly locate target defects.

Description

Products Advantages

1.The X-ray source adopts a closed X-ray tube, featuring long lifespan, maintenance-free operation, and 130KV voltage.

2.The new-generation high-definition digital flat-panel the xray inspect detector, with high-resolution design, delivers optimal images in an extremely short time.

3.Laser automatic navigation and positioning enable quick selection of the shooting position.

4.X/Y/Z axis motion control for easy operation.

5.CNC inspection mode for fast automatic detection of multi-point arrays.

6.Tiltable angle: ±60°; multi-angle tilt inspection makes it easier to detect sample defects.

7.Optional 360° rotation function. X ray machine for pcb

8.Visualized high-definition navigation window for convenient operation and quick location of the inspection target.

9. The industrial xray inspection system has 550mm*550mm loading stage.

10.Simple and fast operation allows quick identification of target defects; users can get started after 2 hours of training.

Products Specifications

| X-ray Source |

Type: Closed reflective target microfocus Voltage: 40-130KV (configurable) Current: 10-300uA Max Power: 39W Microfocus Size: 5μm |

| Flat-Panel Detector |

Type: Amorphous silicon flat-panel Pixel Matrix: 1536×1536 Field of View: 130.56×130.56mm Spatial Resolution: ≥5.5Lp/mm Pixel Pitch: 85μm |

| Loading Stage |

Size: 550×550mm Inspection Range: 500×500mm Max Load: 10kg Radiation Isolation: 5mm thickened lead plate |

| Chassis & Electrical |

Dimensions: 1450(L)×1530(W)×2000(H)mm Weight: ~1500kg Power Supply: AC220±10% 10A Total Power: 1500W |

| Safety & Environment |

Operating Env: 22±3℃, 50%RH±10%RH Radiation Safety: ≤1μSV/H (meets international standards) Key Protections: Interlock, electromagnetic window lock, emergency stop |

| Dimensions | 1450mm(L) × 1530mm(W) × 2000mm(H) |

| Weight | Approx. 1500kg |

| Power Supply | AC220±10% 10A |

| Total Power | 1500W |

| Temp & Humidity | 22±3℃, 50%RH±10%RH |

| Radiation Protection | Steel-lead-steel structure; leaded glass windowDose rate ≤1μSV/H (meets international standards) |

| Key Protections | 1. Safety interlock (door open → X-ray disabled)2. Electromagnetic window lock (X-ray on → window locked)3. Emergency stop button (one-press power cut) |

| Manufacturer | Shenzhen Dinghua Innovation Automation Co., Ltd.(X-RAY / BGA rework station specialist) |

| Safety Interlock | 3 high-sensitivity limit switches are installed at the front and rear door positions. When the door is opened, the X-ray source is automatically protected and the X-ray tube cannot be activated. |

| Electromagnetic Safety Door | The observation window is equipped with an electromagnetic switch. When the X-ray tube is in operation, the observation window cannot be opened. |

| Emergency Stop Button | In case of emergency, press to cut off power immediately. |

Software functions

| Function Module | Description |

|---|---|

| Operation Method | All operations are completed via joystick + keyboard + mouse (the motion axis can be moved by dragging the mouse; the X-ray tube Z-axis can be zoomed in/out via pulley sliding). |

| X-ray Tube Control | Click the button with the mouse to turn the X-ray on/off; the tube voltage and tube current values are displayed in real time. Adjustments can be made via up/down buttons, slider dragging, or manual input; the tube power and microfocus size are also displayed in real time. |

| Status Bar | Indicates interlock status, preheating status, and X-ray on/off status through red/green flashing lights. |

| Category | Item | Description |

|---|---|---|

| (General Functions) | Image Effect Adjustment | Freely adjust the image's filter level, brightness, contrast, and filter to achieve the desired image effect. |

| Navigation Window | After the high-definition color camera captures the platform image, click any position on the photo to quickly locate the inspection target. | |

| Motion Axis Status | Displays real-time coordinates and magnification rate. | |

| Inspection Results | Sequentially displays each measurement result (void rate, distance, area, and other measurement items). | |

| Speed Control | Adjust the axis movement speed (slow, normal, fast) via the space bar and software. | |

| Void Rate Measurement | Automatic Calculation | Measure voids in packaged components (e.g., BGA, QFN); automatically calculate the BGA void proportion in the selected area. Set thresholds to automatically determine void rate and maximum void rate. |

| Parameter Adjustment | Adjust thresholds, size, Blob type, and calculation parameters to get accurate automatic calculation results. | |

| Dimension Calculation | Through-Hole Solder Ratio Calculation | Mainly used to measure the wetting rate of through-hole components; obtain the proportion and height of the component's soldering surface via rectangular selection. |

| Quick Distance Measurement | Get the distance between two points via arbitrary frame selection. | |

| Point-Line Distance | Get the distance between a point and a line via arbitrary point and line selection. | |

| Angle | Set points A and B as the baseline, then click point C to measure the included angle between rays BA and BC. | |

| Circle | Mainly used to measure circular components (e.g., solder balls); select any circular component via frame selection to get its circumference, area, and radius. | |

| Horizontal Rectangle | Mainly used to measure square components; select a square via frame selection to get its length, width, and area. |

| Automatic Inspection | Item | Description |

|---|---|---|

| CNC Inspection | For multiple inspection points, simply set any position and measurement items; the software will automatically capture each inspection point and save the images. | |

| Laser Positioning | Red dot laser positioning device, dual assistance for easy navigation. |

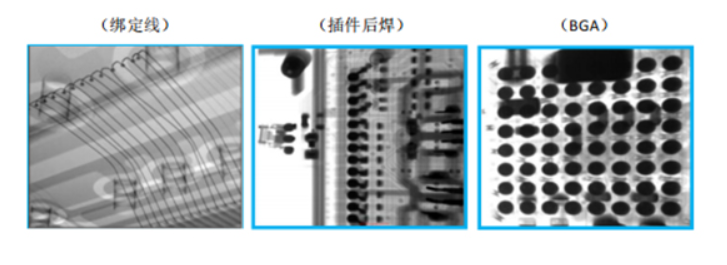

Example images