X-ray Parts Counter Machine

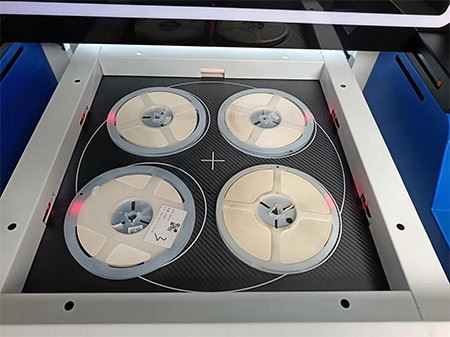

The X-RAY component counting machine is used for rapid counting of reel-type materials used in SMT industry production. It is designed and assembled with intelligent modular design, adhering to Industry 4.0 standards. It can handle a full range of components including 7-17 inch TapeReel/Tray/1C, and is equipped with artificial intelligence deep learning software and a cloud-based update system. Using X-ray imaging technology, it inspects production materials and acquires image information. This information is then processed using image algorithms for rapid counting, determining the actual quantity of materials. The system can also categorize and statistically analyze the material quantities by type, and integrate the data with the ES system.

Description

Products Description

The X-RAY component counter(x ray reel counter) is used for rapid counting of reel-packed materials in SMT industry production. It adopts smart modular design and assembly in line with Industry 4.0 standards.

This xray parts counter it is compatible with full-range components such as 7-17 inch TapeReel/Tra/IC. Equipped with artificial intelligence deep learning software and a cloud update system.

By leveraging X-ray imaging technology, it inspects production materials and captures image information. Then, it performs rapid counting via image algorithms to obtain the actual quantity of materials. Meanwhile, it can classify and count material quantities by category, and connect the data information to the MES system.

Products advantages

| High Speed | Counting 01005, 4 reels*20000pcs in 7s |

|

99.99% Accuracy |

AI recognition for BGA,QFN,LED and resistors etc. |

| Data Traceability | Auto-report with LOT No./PN for ERP/MES |

| Save Labor Cost | Replace 4+ manual operators |

| Wide Compatibility | Supports tapes,reels, trays, tubes, max 17" |

| Xray safety | <0.2 µSv/hr - 0.5 cm from surface, meeting all international standards |

| Max reels | 17''/430mm |

| Min reels | 2'' /50mm |

| Xray tube | 50KV, (80KV is optional) |

| Dimension |

1500× 900×1950mm |

| Weight | 500kg |

Products Application

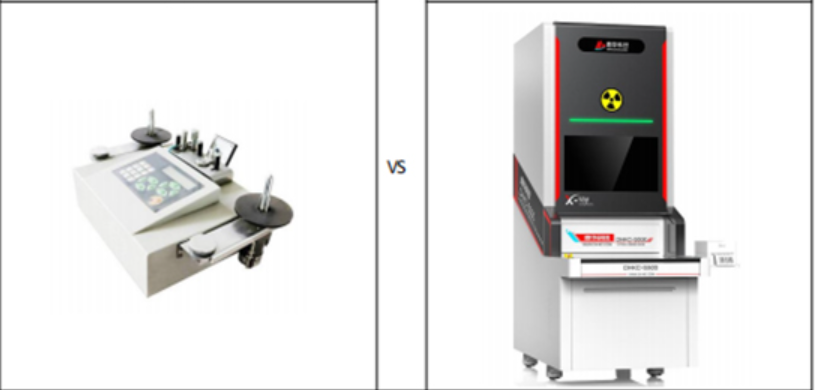

Traditional Counter vs. Dinghua Smart Component Counter

| Comparison Item | Traditional Counter | Time Consumption | VS | Time Consumption | Dinghua Smart Component Counter |

|---|---|---|---|---|---|

| Efficiency | - Manual scanning & verification: 10S- Manual loading + empty tray placement + material rewinding: 20S- System counting (transfer from one tray to another): 60S- 8 devices/8 workers for 400 trays: 1H | 10S/20S/60S1H | 6-10S1H | - Place materials directly on the workbench, press start to auto-scan- Uses X-ray imaging + self-developed AI algorithm for fast counting- Data upload to MES/ERP systems- 1 device/1 worker for 400 trays: 1H(Saves 7 workers) | |

| Quality | - Material tape rewinding risks: leaded IC deformation → poor soldering- Material damage: tray parts falling/tilting → missing components; empty slots/picking errors- MSD components: unpacking increases exposure time → material deterioration | / | / | - No rewinding needed: no material damage/deformation risk- Scan original packaged materials: avoids missing components/empty slots; reduces waste- MSD components: no unpacking → less exposure; no moisture damage/quality risks | |

| Error Rate | - Multiple processes rely on manual work: counting errors, tray replacement mistakes, system data update errors- Empty slots counted as materials | / | / | - Full AI-based inventory: smart scanning + auto-upload- Less manual reliance; empty slots excluded from counting |

Summary: Traditional counters are time-consuming, inefficient, high-risk for quality issues, and prone to errors. The smart component counter improves efficiency by 5-7 times, eliminates quality risks, and avoids errors.

Products package

Products Service

We provide end-to-end service for your X-ray counter machine(DHKC-S600), known as SMD component counter

or automatic IC counter systems:

Precision Maintenance: Calibration & certification to ensure 99.98% counting accuracy for SMT material management.

Rapid Repairs: Minimize downtime with on-site/remote support for electronic part inventory workflows.

Process Integration: Optimize X-ray/SMD counters for seamless production line to dock ERP or MES.

Training & Upgrades: Empower teams to operate automatic IC counters and leverage data for inventory control.

Custom Solutions: Tailor services for hybrid SMT material and component counting needs.

Free Training: Online/On-site operation training

Warranty: 1 year for machine, lifetime software upgrade

Products video

Video for Automatic X-ray component counter: