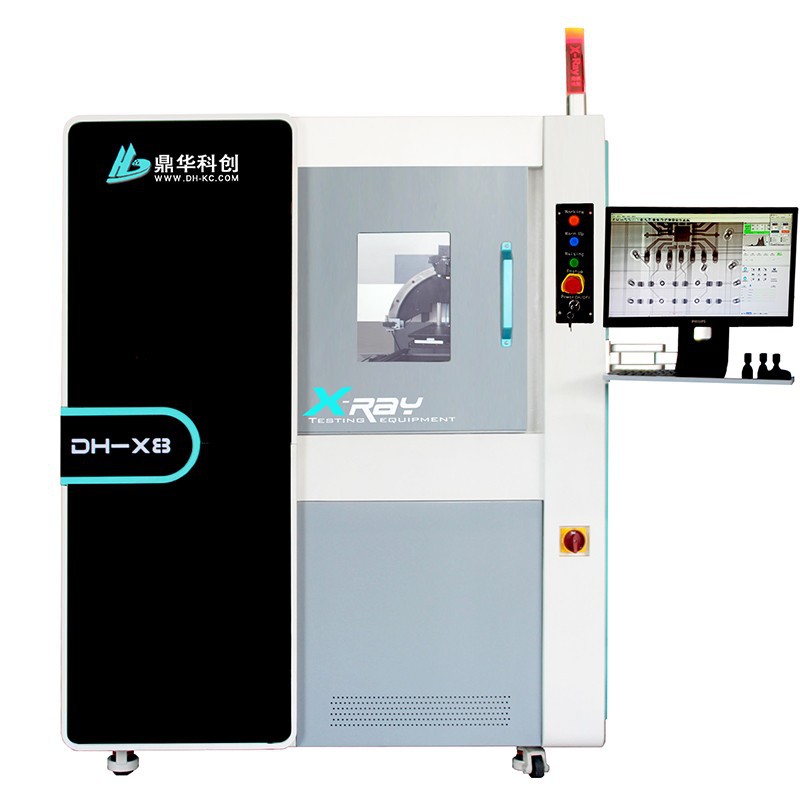

PCB X-ray Inspection Equipment

The Dinghua DH-X8 high-precision X-ray inspection equipment features automatic ON/OFF control of the X-ray tube for batch sample inspection. Equipped with a 90KV Hamamatsu X-ray tube, it achieves a detection accuracy of 5um. It utilizes a high-resolution digital X-ray flat panel with 1536*1536px resolution for clearer images. Geometric magnification is 450x, and system magnification is 2000x. The 540*540mm stage accommodates a large number of samples of various sizes. It offers semi-automatic NG/OK product detection and allows for 60° tilted observation.

Description

Features and Advantages

1.Loading Stage (Motion):The X-ray inspection machine loading stage can move along X and Y directions.

Larger effective inspection range, improves product magnification rate and inspection efficiency (360° rotating loading stage optional).

2.Image Detector (Tilt):The Non-destructive X-ray testing of image detector can tilt at 60°.

Easily observe side defects of products, such as BGA cold solder joints, through-hole solder penetration, etc.

3.X-ray Source:Uses Japan Hamamatsu enclosed X-ray tube, long lifespan and maintenance-free.

4.X-ray Reception: High-definition digital flat-panel detector.

5.Visualized Automatic Navigation Window:Easy to operate, quickly locate the inspection target position.

6.Loading Platform:SMT X-ray inspection for PCBA has ultra-large inspection space, size: 550*670mm (suitable for extra-large main control boards, LED light strips, etc.).

7.Editable Inspection Program:Suitable for mass automatic inspection, improves efficiency, and automatically detects NG (non-conforming) products.

8.Rework Database Management: Can save edited inspection programs and inspection result images.

9.MWS/ERP System: Customizable integration available for convenient management.

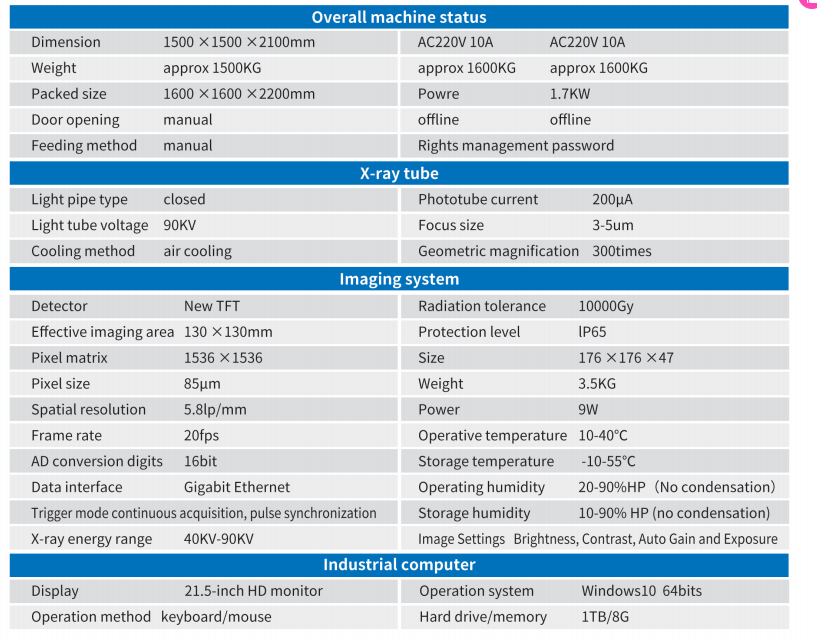

Product Specification

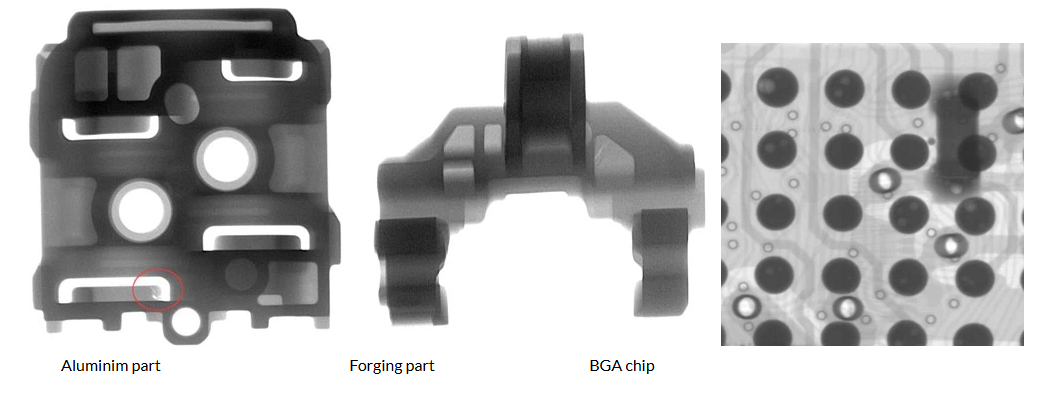

Products Application

With the increasing demand for electronic devices, the need for quality control has become paramount. X-ray inspection is

an essential tool in ensuring that the electronic components are manufactured to the highest standard. This not only helps

to prevent defects but also ensures that the final product is of the highest quality, thus increasing customer satisfaction.

Moreover, electronic x-ray inspection has significantly reduced the likelihood of product recalls and returns, as potential

defects are identified and corrected before the products are released. This has saved companies a significant amount of money,

time, and resources that would have been lost in the event of a recall.

Our production and equipment

Our free service hotline: +86-151-7443-3187

14

years

We have been working in the industry since 2011

32

certificates

We have obtained most of the professional certificates in the industry and insist on international standards of production.

18

awards

We have won a lot of awards for strong creativity