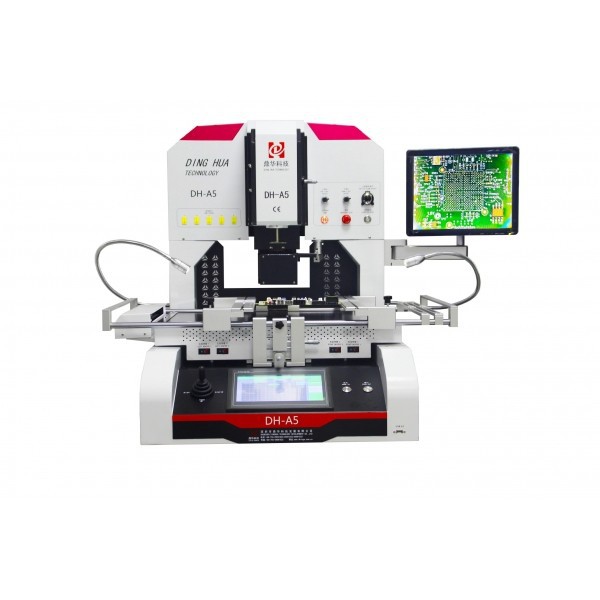

Motherboard Automatic Repair Machine

Dinghua's DH-A5 fully automatic optical alignment BGA rework station employs a servo motion control system, enabling automated control of three modes: soldering, placement, and removal. It is stable, reliable, safe, and highly efficient, completely freeing up labor.

Description

Product Parameters

|

Total Power |

6800W |

|

Top heater |

1200W |

|

Bottom heater |

The second temperature zone is 1200W, and the third temperature zone is 2700W. |

|

power |

AC220V±10% 50/60Hz |

|

Dimensions |

L650×W700×H850 mm |

|

Positioning |

V-shaped slot, PCB bracket can be adjusted in either X or Y direction and equipped with a universal clamp. |

|

Temperature control |

K-type thermocouple(K Sensor) Closed loop control |

|

Temp accuracy |

±1℃ |

|

PCB size |

Max 500×450 mm Min 10×10 mm |

|

Workbench fine-tuning |

±15mm front and back, ±15mm left and right |

|

Camera magnification |

10x-100x times |

|

BGA chip |

2X2-80X80mm |

|

Minimum chip spacing |

0.1mm |

|

External Temperature Sensor |

5个,Scalable(optional) |

|

Placement Accuracy |

±0.01MM |

|

Net weight |

92kg |

| Key Features | bga optical alignment system, automatic bga rework station,infrared bga rework station |

Product Description

1. Integrated Control System

This bga optical alignment system embedded industrial computer with HD touchscreen HMI and PLC control supports real‑time temperature curve display, analysis, correction, and multi‑curve monitoring. Password‑protected startup and curve editing ensure operational security.

2. Precision Temperature Control

High‑accuracy K‑type thermocouple closed‑loop PID control with auto‑compensation maintains temperature within ±2 °C. External calibration interface allows precise curve verification and adjustment.

3. Automated Motion & Positioning

Servo‑driven XYZ axes with V‑groove and linear slide positioning enable fast, fine‑adjustable PCB handling for varied layouts and sizes.

4. Flexible Fixturing

Universal movable clamp protects PCB edges from damage and deformation, compatible with multiple BGA package dimensions.

5. Interchangeable Nozzles

360°‑rotatable titanium alloy nozzles in multiple sizes allow quick installation and replacement.

6. Multi‑Zone Heating

Three independently controlled heating zones (top/bottom) with adjustable temperature, time, slope, cooling, and vacuum settings via HMI.

7. Programmable Profiles

Up to 8‑segment temperature curves per zone, with extensive storage and touchscreen‑based editing, analysis, and recall for different BGA types.

8. Visual Alignment System

High‑precision digital video alignment with joystick‑controlled lens movement ensures full‑view inspection of BGA corners and center, eliminating blind spots.

9. Rapid Cooling

High‑power cross‑flow fan quickly cools PCB after soldering to prevent warping.

10. Voice Alert

Audible pre‑warning 5‑10 seconds before process completion prompts operator readiness.

11. Auto‑Cooling Protection

Cooling system activates after heating stops and shuts off at room temperature to prevent device overheating and aging.

12. Fully Automated Handling

Integrated BGA pick‑and‑place system enables intelligent, hands‑free operation for improved efficiency.

13. Safety & Certification

CE‑compliant with emergency stop and auto‑power‑off protection for accident prevention.

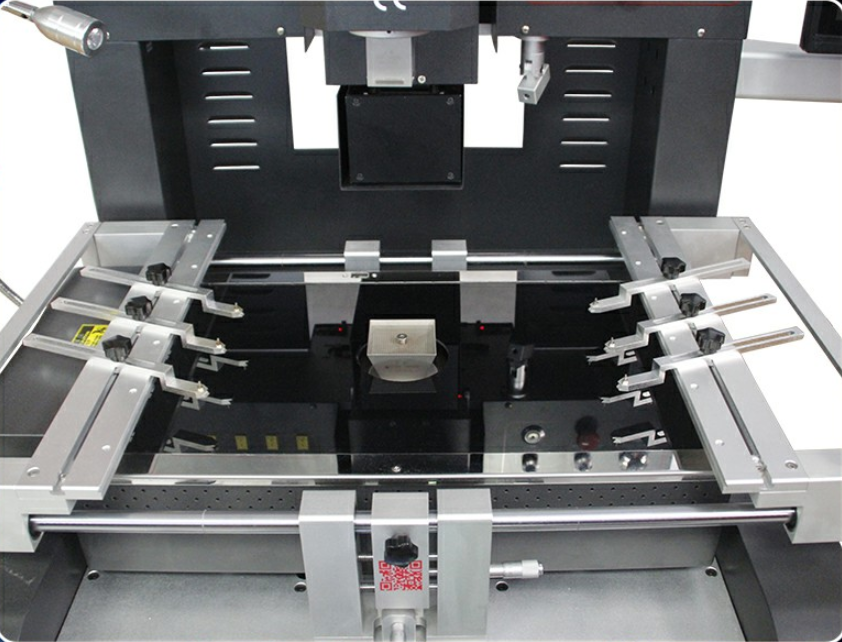

Detail Images

This automatic bga rework station employing a precise PID program, it tracks and monitors at a rate of 20 milliseconds per cycle, providing real-time feedback for more accurate temperature display, smaller errors, and greater stability!

The preheating zone of infrared bga rework station uses infrared LEDs, which ensure rapid heating, stable temperature control, environmental friendliness, energy efficiency, and an attractive appearance,and long lifespan.

With laser positioning, PCB loading is quick and accurate in just one step.

Optical positioning ensures precise chip mounting alignment.

Adaptable positioning system for easy placement of PCBs of all shapes and sizes.

why choose us

Since it's establishment in 2011, Shenzhen Dinghua has remained dedicated to the field of automation equipment,

serving as both a pioneer and a leader in the industry.

why choose our products

1. We are a professional BGA rework station manufacturer with over 14 years of experience in design, development, production, and sales.

2. Our machines offer the best quality at competitive prices.

3. Fast delivery options include FedEx, DHL, UPS, TNT, EMS, and shipping by sea or air.

4. OEM and ODM services are welcomed.

5. Free technical consultation and video demonstration available.

6. 1-year warranty for the entire machine (excluding consumables).

Our Partners

Dinghua machine with a good reputation,excellent quality and sound after-sales service to win the world praise,in many domestic and foreign enterprises shine!