Ball Grid Array Rework Station

The DH-A2E represents a leap forward in rework technology, combining industrial automation with sub-millimeter precision to tackle the most challenging PCB repairs. This fully-featured ball grid array rework station is built for environments where repeatability, uptime, and flawless results are non-negotiable.

Description

DH-A2E: The Next Evolution in Automated Precision Rework

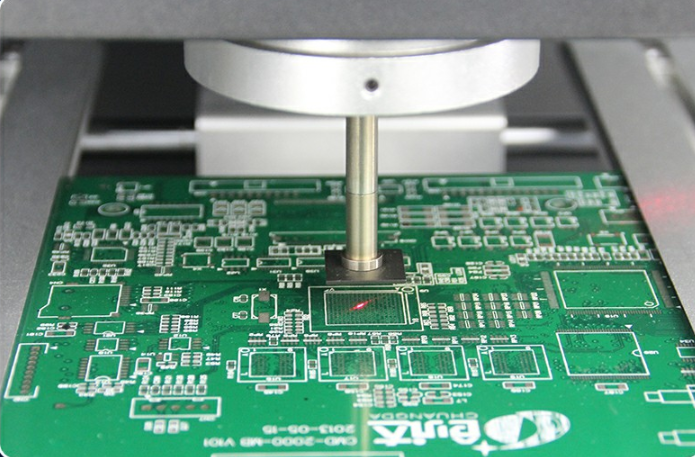

The DH-A2E sets a new benchmark for automated, high-precision PCB repair. Designed as an advanced ball grid array rework station, it integrates optical alignment with fully automated pick-and-place, desoldering, and soldering cycles, significantly reducing operator dependency and human error.

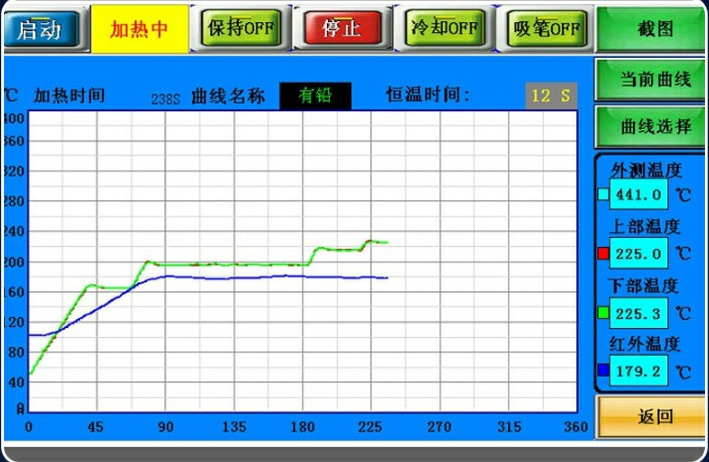

Engineered for both accuracy and ease of use, this smd rework station achieves remarkable specifications: temperature control within ±1°C and positioning accuracy of 0.01mm. Its intuitive touch-screen interface with pre-loaded programs allows technicians of all skill levels to execute complex rework bga automatic processes with confidence. From delicate micro-BGAs to large components, the DH-A2E handles a wide range of SMT repairs, making it the ideal cornerstone for any modern electronics repair lab or production line seeking to boost yield and consistency.

Products Advantages

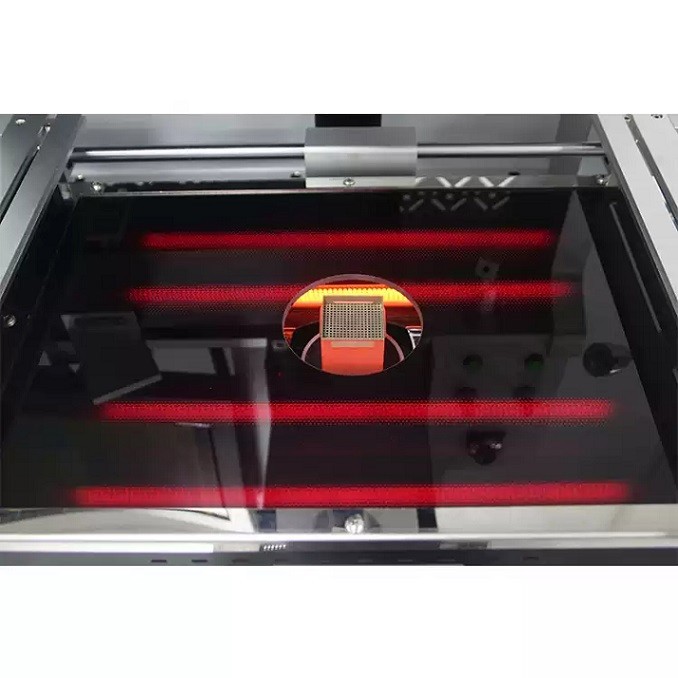

1.Fully Automated Rework Cycle: Experience true hands-off operation with automatic chip removal, placement, and soldering. The integrated vision system and automated material handling (pick, feed, camera positioning) complete a rework bga automatic process that minimizes manual intervention and maximizes throughput.

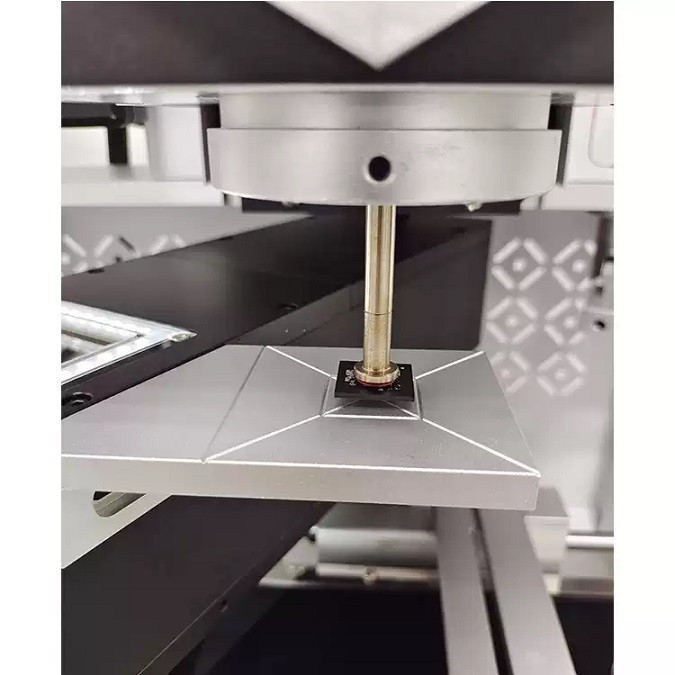

2.Sub-Millimeter Precision Alignment: An integrated high-precision optical alignment system, combined with a motorized linear slide (X, Y, Z-axis fine adjustment), ensures component placement with an accuracy of 0.01mm, virtually eliminating misalignment.

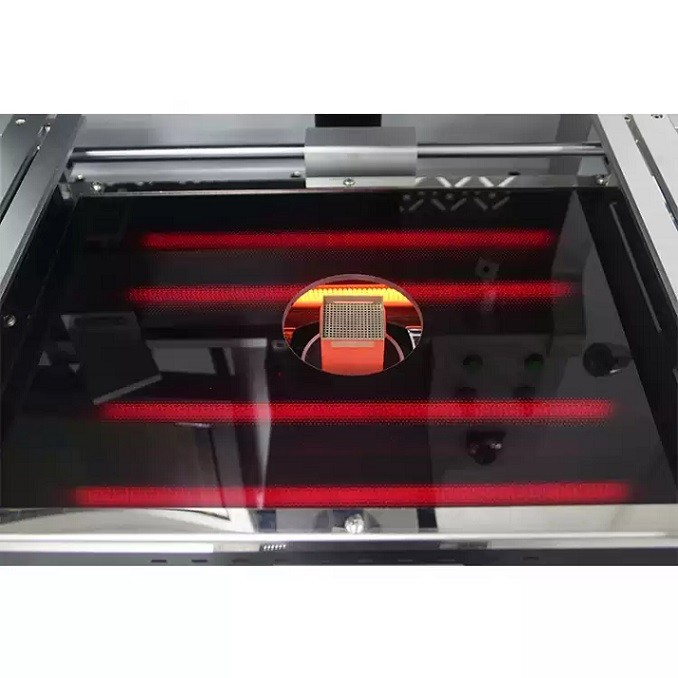

3.Industrial-Grade Thermal Management: A three-zone independent heating system (top, bottom, preheat) with closed-loop K-type thermocouple control maintains a temperature deviation within ±1°C. The large-area lower heater accommodates various PCB sizes for uniform heating.

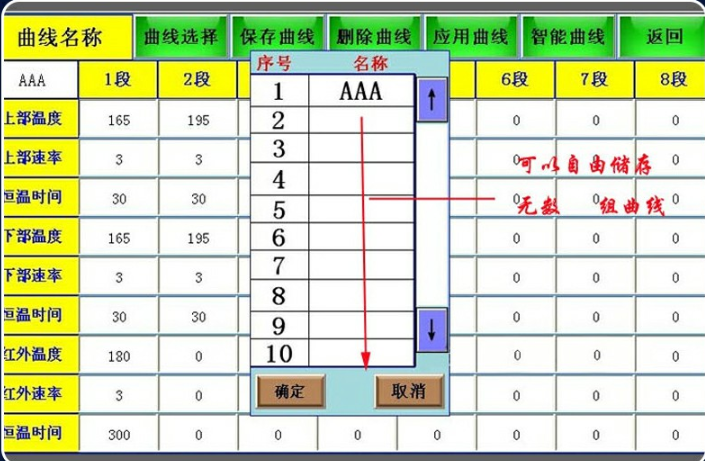

4.Intuitive Touch-Screen Control: The industrial PC with HD touchscreen and PLC control offers both manual and automatic modes. It provides real-time temperature curve graphing, analysis, and stores vast profiles for one-touch operation, simplifying complex tasks.

Products Parameters

| Category | Specification |

|---|---|

| Model | DH-A2E |

| Total Power | 5700W |

| Heating Zones | 3 (Top: 1200W, Bottom Zone 2: 1200W, Zone 3: 3200W) |

| Power Supply | AC220V ±10%, 50/60Hz |

| Temperature Control | Closed-loop with K-Type Thermocouple |

| Temperature Accuracy | ±1°C |

| Positioning Accuracy | 0.01mm |

| Max. PCB Size | 450 x 500 mm |

| Min. PCB Size | 10 x 10 mm |

| Compatible Chip Size | 2x2 mm to 80x80 mm |

| Min. Chip Pitch | 0.1mm |

| Dimensions (LxWxH) | 600 x 700 x 850 mm |

| Net Weight | 70 kg |

Designed for the Professional Workshop:

Beyond core specs, the DH-A2E is built for daily professional use. Features like adjustable airflow for small components, 360° rotatable nozzles, universal fixtures, rapid cooling, and voice alerts create a seamless workflow. Its rugged smd rework station construction, CE certification, and emergency safety features ensure reliable and safe operation in demanding settings.

Ideal For: Electronics Manufacturing Services (EMS), high-reliability repair centers (automotive, aerospace, medical), R&D departments, and any operation requiring dependable, automated precision rework.

Products Details

Our Company

Shenzhen Dinghua Technology: Precision Engineered for Your Success

In the world of advanced electronics, where component density soars and tolerances shrink to microns, precision is not just an advantage-it is an imperative. Shenzhen Dinghua Technology was founded in 2011 with a clear mission: to equip manufacturers and repair specialists with the intelligent tools needed to master this complexity.

We stand at the intersection of vision and action. Our portfolio of high-performance X-ray inspection systems and automated BGA rework stations is engineered to transform critical challenges-from detecting hidden solder defects to executing flawless microprocessor repairs-into reliable, repeatable processes.

What Defines Dinghua Technology?

Deep Industry Roots: We don't just sell equipment; we cultivate expertise. Our dedicated R&D team lives at the forefront of SMT and NDT technology, ensuring our solutions are born from a profound understanding of your real-world production and repair floor challenges.

The Bridge to Intelligence: We specialize in creating synergy. By integrating precise mechanics with smart control systems and insightful software, we deliver more than standalone machines-we provide connected workflows that enhance decision-making and traceability.

Partnership Beyond the Product: Our commitment crystallizes after installation. We offer comprehensive technical support, application assistance, and responsive service, forming partnerships aimed at maximizing your operational uptime and return on investment.

Driven by a culture of pragmatic innovation and unwavering integrity, we are dedicated to advancing the standards of quality and efficiency in electronics manufacturing and repair worldwide. Let's build the future of precision, together.

Packaging&Delivery