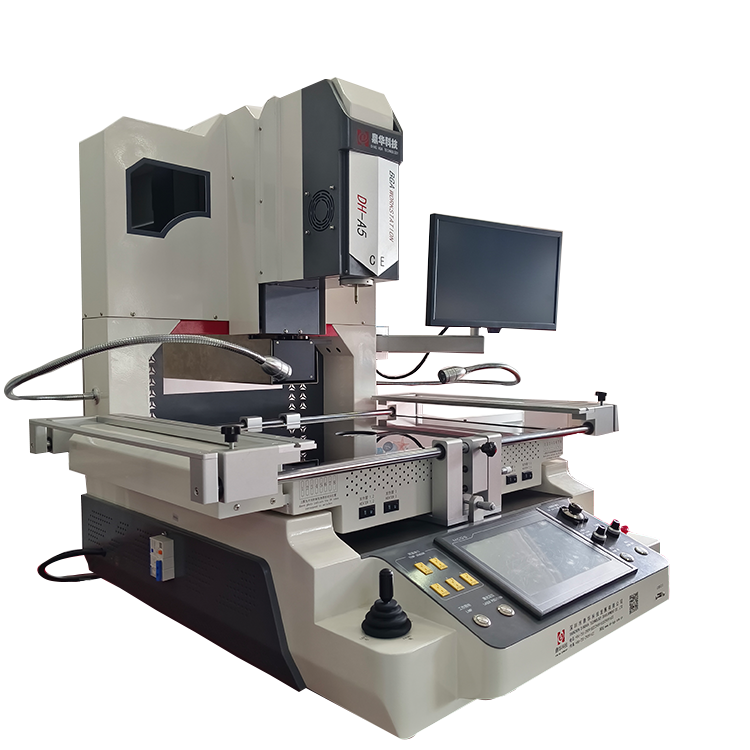

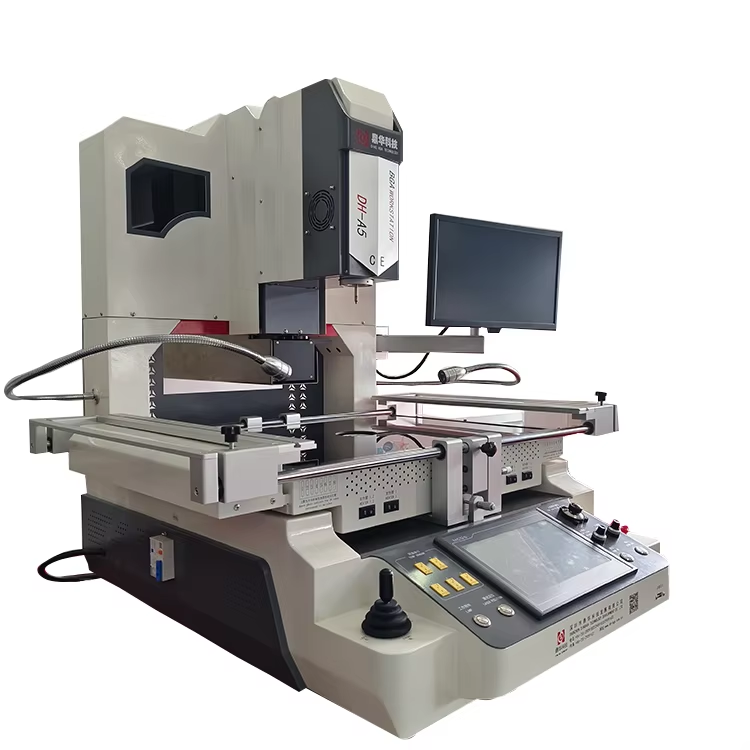

Precision BGA Rework Station

The DH-A5 is a high-performance, fully automatic BGA rework station used for precision repairing of a wide range of SMD devices. Engineered by Dinghua Technology, a leader in BGA and X-ray inspection technology, this station combines advanced optical alignment with intelligent automation to deliver professional-grade results for complex motherboards. As an advanced optical precision BGA rework station, it provides unparalleled accuracy, and with its integrated features, it functions as a complete BGA soldering and desoldering station, ensuring top-tier performance for all your rework needs.

Description

Products Description

The DH-A5 is a highly advanced precision BGA rework station used for automatic alignment and soldering of a wide range of SMD devices, delivering professional-level repair quality. Manufactured by Dinghua Technology, a leader with over ten years of experience in both BGA and X-ray inspection technologies, this optical BGA rework station combines cutting-edge features to ensure highly precise automated alignment. Its advanced optical system allows the BGA soldering and desoldering station to achieve high-quality results, even on the most complex motherboards.

Products Core Features

Fully Automated Process: The DH-A5 offers automatic disassembly, welding, and chip recovery, significantly reducing labor intensity.

Precision Optical Alignment: Features a high-definition 6-million-pixel CCD digital camera and a Panasonic optical counterpoint system. This system allows for precise chip placement and alignment, effectively eliminating misalignment or offset.

Intelligent Temperature Control: Utilizes a high-precision K-type thermocouple closed-loop system and independent PID algorithms across three heating zones to maintain temperature accuracy within ±1°C.

Massive Profile Storage: The station can store up to 50,000 groups of temperature profiles, allowing for easy recall and consistency across various repair tasks.

Laser Positioning: Includes laser positioning to quickly find the vertical point of the temperature zones and the central point of the BGA chip.

User-Friendly Interface: Equipped with an 8-inch high-definition touchscreen and PLC control, allowing operators to manage heating profiles and view real-time temperature curves.

Products Specification

|

Item

|

Parameter

|

|

Power supply

|

AC220V±10% 50/60Hz

|

|

Total power

|

9200w

|

|

Top heater

|

1200w

|

|

Bottom heater

|

1200w

|

|

IR Preheating Area

|

6400w

|

|

Operation mode

|

Fully automatically disassemble, suction, mounting and soldering

|

|

Chip feeding system

|

Automatic receiving, feeding, automatic induction (optional)

|

|

Temperature profile storage

|

50000 groups

|

|

Optical CCD lens

|

Automatic stretch out and go back

|

|

PCBA positioning

|

Up and down intelligent positioning,bottom "5-point support" with V-groove fixed PCB which can be adjusted freely in the X-axis

direction, with universal fixtures meanwhile

|

|

BGA position

|

Laser position

|

|

Temperature control

|

K-type Sensor,Closed loop and 8~20 segments for temperature controlling program

|

|

Temperature accuracy

|

±1 ℃

|

|

Positon accuracy

|

0.01mm

|

|

PCB size

|

Max 640*560 mm Min 10*10 mm

|

|

PCB thickness

|

0.2-15mm

|

|

BGA chip

|

1*1-100*100mm

|

|

Minimum chip spacing

|

0.15mm

|

|

External Temperature Sensor

|

5 pcs(optional)

|

Products news

The precision BGA Rework Station is an indispensable tool in the industry of repairing electronic devices. Because of technological advancements in the processes of BGA soldering and desoldering, there is now a substantial increase in demand for these types of high-performance rework stations, thereby evolving the way that repairs are performed for everything from cell phones to laptops.

Dinghua Technology, a well-known brand in the world of optical BGA rework stations, has stepped up innovation by introducing several new models of the BGA soldering and desoldering station. These new technologies use multi zone heating, optical alignment, and Intelligent automation to provide customers with the highest degree of accuracy and efficiency. With increasing miniaturization and complexity in electronic designs, the demand for precision rework equipment has never been higher.

As one of Dinghua's premier models, the DH-A5 combines cutting-edge optical BGA rework station technology and high precision automated alignment/soldering capability. This allows the operator to use an automated process to position and solder micro-components (BGA, QFN, CSP) found on devices like smart phones/laptop computers, etc., as well as those found on high-performance circuit boards.

The demand for smaller, more sophisticated electronic products means that the need for precision rework technology will continue to increase, and the use of BGA rework stations has given technicians the ability to perform repairs with a level of accuracy that was not possible with older methods.

With companies such as Dinghua Technology paving the way for the future of BGA rework, and with the continuing growth of automation and precision in the industry, the future of BGA rework is very bright and creates an opportunity for both manufacturers and consumers to benefit from high-quality repairs and longer device lifecycles.

For more information about the latest in BGA rework stations and their capabilities, visit website: www.dhsinobgas.com / www.xraybgamachine.com and contact us!