PCB Rework System

The PCB Rework System DH-5880 is designed for professional PCB repair applications. It is a hot air soldering and desoldering machine capable of handling various types of chips, including POP, SOP, QFN, BGA, and more. The system simulates the reflow soldering process and uses segmented heating to minimize thermal stress and reduce the risk of damage to the PCB.

Description

Products Description

The PCB rework system DH-5880 is a professional PCB repair tool. Equipped with three independent temperature zones (including top heater, bottom heater and infrared reheating zone), HD touch screen, vaccum sucker pen, four external temperature sensor, laser pointer, USB port. It is used for various motherboard repair such iPhone, iPad, Macbook, xBox playstation and other electronics.

The PCB rework system is a specialized tool used for the soldering and desoldering of BGA and other surface-mount components on PCB boards. It typically features precise temperature control, hot air heating or infrared heating, and adjustable fixtures to support stable and accurate chip repair. This type of rework station is widely used in electronics repair, and small-batch manufacturing for devices such as laptops, mobile phones, game consoles, and various PCB assemblies.

Products Pictures

Belowing is the pictures of DH-5880 from four different angles:

Products Specification

|

Item

|

Parameter

|

|

Total Power

|

5500w

|

|

Top heater

|

1200w

|

|

Bottom heater

|

1200w ( the second temperature zone)

|

|

Infared heater

|

3000w ( the third temperature zone)

|

|

Operation mode

|

Touch screen+manual

|

|

Dimensions

|

L500*W600*H700mm

|

|

Temperature profiles storage

|

50000 groups

|

|

PCB positioning

|

V-groove + universal fixture + 5-points support + Adjustable in X direction

|

|

BGA positioning

|

Laser pointing at its center

|

|

Temperature control

|

K-type Thermocouple + Closed Loop + Auto compensation

|

|

Temperature accuracy

|

±2℃

|

|

PCB size

|

Max 450*380mm Min 10*10mm

|

|

BGA size

|

1*1-80*80mm

|

|

BGA absorption mode

|

Vacuum suction pen

|

|

Minimum chip spacing

|

0.1mm

|

|

External temperature sensor

|

4, optional

|

|

Machine type

|

desktop

|

|

Net weight

|

48kg

|

Products Details

start: switch on headlamp: for lighting, make sure it could be work at dark environment emergency stop : in case of any emergent, press the button immediately

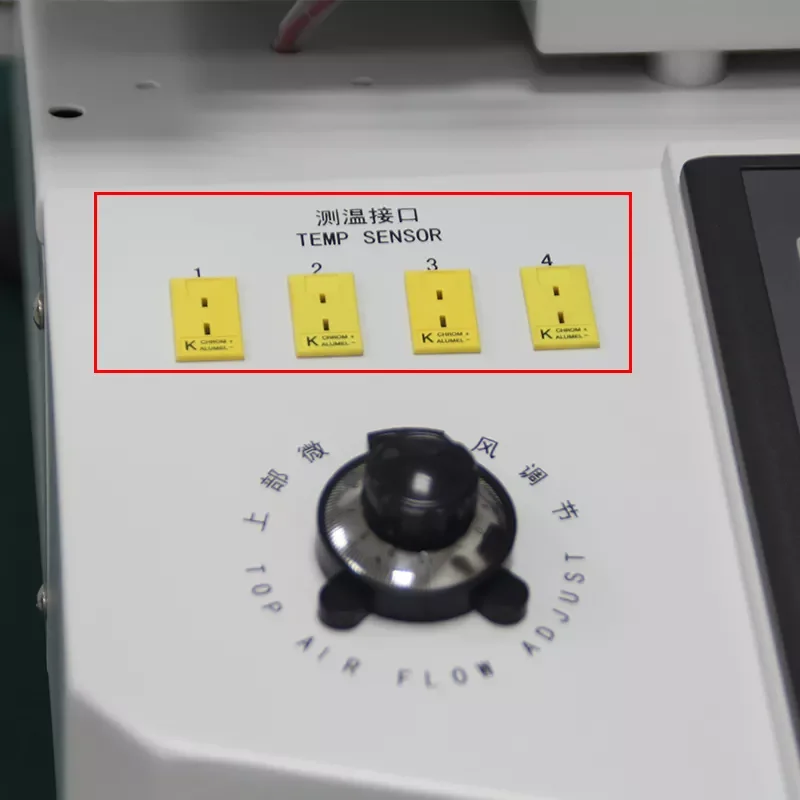

Temp Sensor: 4pcs external temperature testing

Top Air Adjust: adjusting different grades of top hot air

Cross-flow Fan: making PCB and chips cooled after working finshinging or when pressing emergency button down

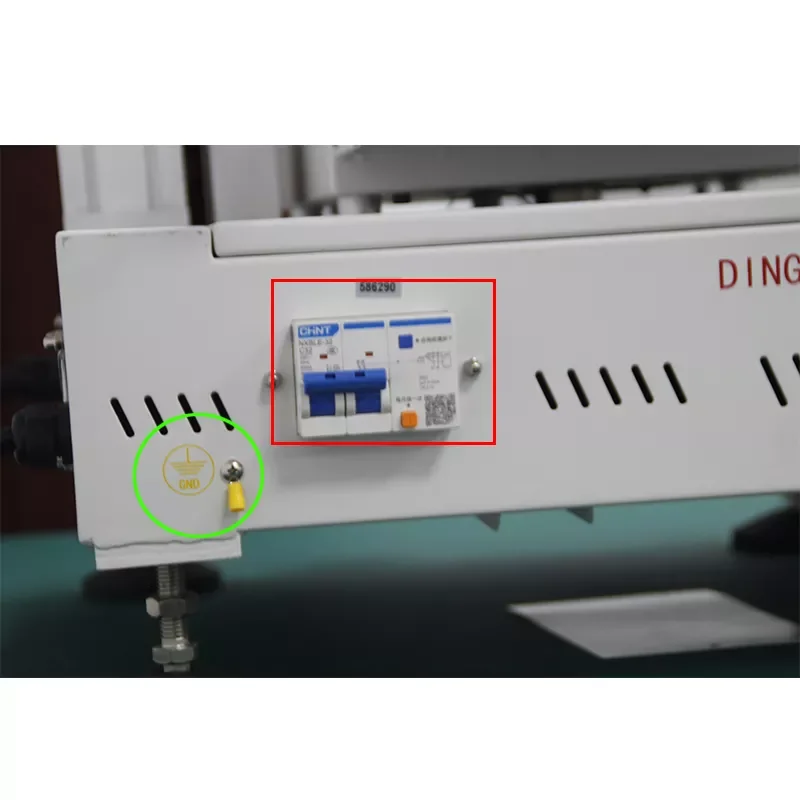

Power switch: whole machine electricy supplying, which provides safer solution when leakage of electricity or short, it will be cut off immediately

HD touch screen: temperature profile,cooling,vaccum sucker pen setting

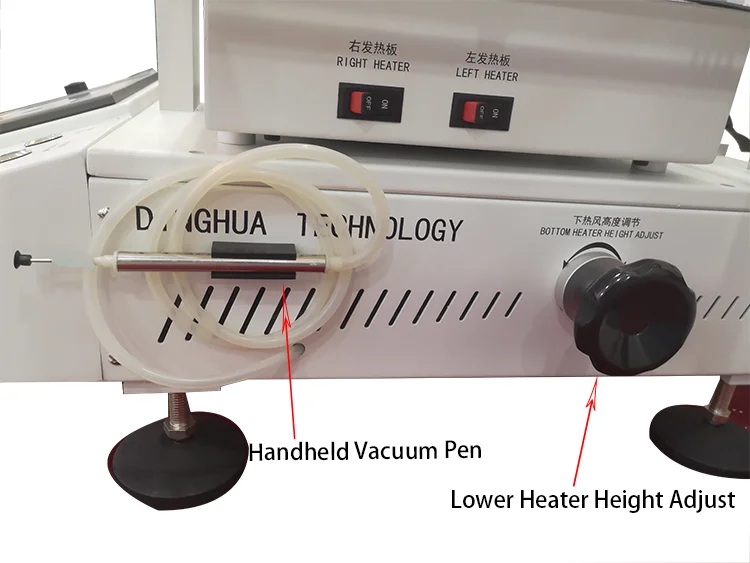

Vaccum sucker pen: Pick up the chip after desoldering

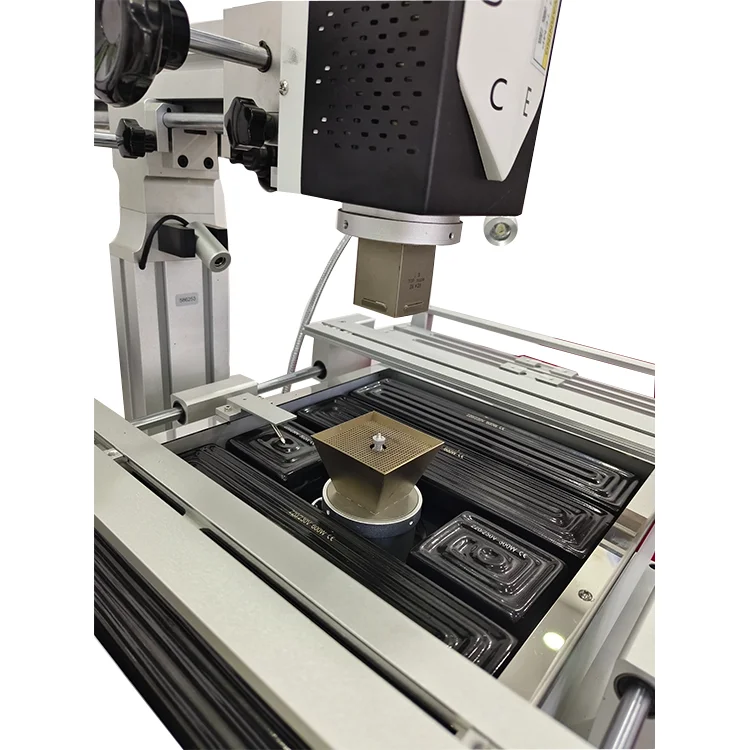

laser pointer: Use to align the position of chips. Pointing at the center the chip

Hot air heating zone (Top heater, bottom heater), infrared preheating zone

Products Application

1. Consumer Electronics Industry

(Mobile phones, tablets, laptops, TVs, gaming consoles)

2. Computer & IT Hardware

(Motherboards, graphics cards, servers)

3. Telecommunications Equipment

(Routers, communication boards, base station modules)

4. Automotive Electronics

(ECUs, sensors, control modules, infotainment systems)

5. Industrial Automation & Control Systems

(PLC boards, control boards, industrial machine electronics)

6. Medical Electronics

(Diagnostic devices, monitoring systems, medical control boards)

7. Aerospace & Defense Electronics

(Navigation systems, control units, mission-critical electronic boards)

8. SMT Manufacturing & Electronics Assembly

(Prototype development, small-batch production, quality rework)

9. R&D Laboratories & Educational Institutions

(Process research, training, and electronics engineering education)

Pakage List

1. Machine:1 set

2. All packed in stable and strong wooden cases,suitable for import and export.

3. Top nozzle: 3 pcs (20*20mm,30*30mm,40*40mm)

Bottom nozzle:2pcs(35*35mm,55*55mm)

4. Beam:2 pcs

5. Plum knob:4 pcs

6. Unicersal fixture:4 pcs

7. Support screw:5 pcs

8. Brush pen:1 pcs

9. Vacuum cup:5 pcs

10. Spanner:3 pcs

11. Temp sensor wire:1 pc

12. Vacuum sucker: 5 pcs

13. Professional Instruction Book:1 pc

14. Tool Box:1 pc