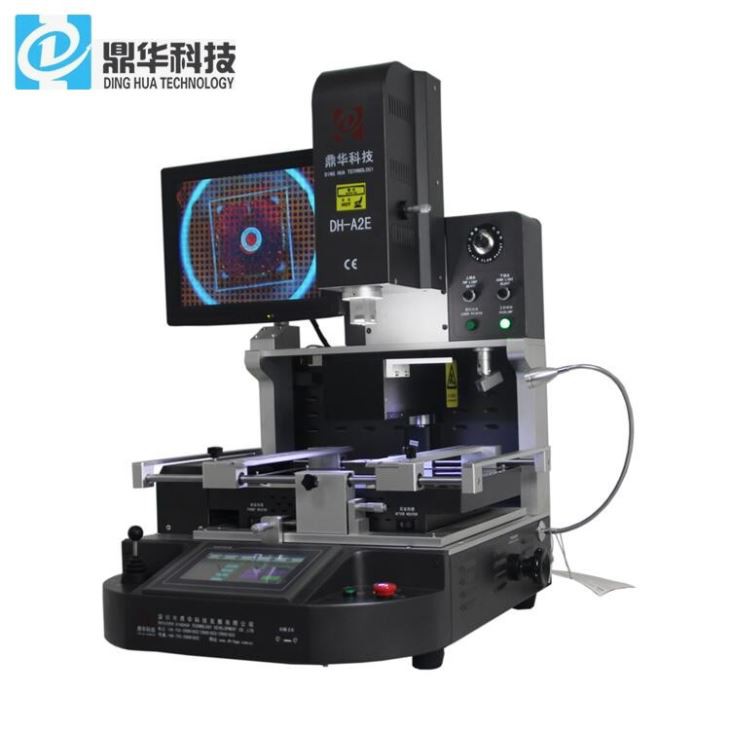

CCD Camera Optical BGA Rework Station

1. Product Introduction GUIDED REWORK! · Highly efficient 1200 W hot air heating head · Focused precise 1200 W hot air lower heating · Large-area IR bottom heating (2700 W) · Integrated vacuum pipette for component removal and placement · Highly accurate placement with integrated force sensor ·...

Description

1. Product Introduction

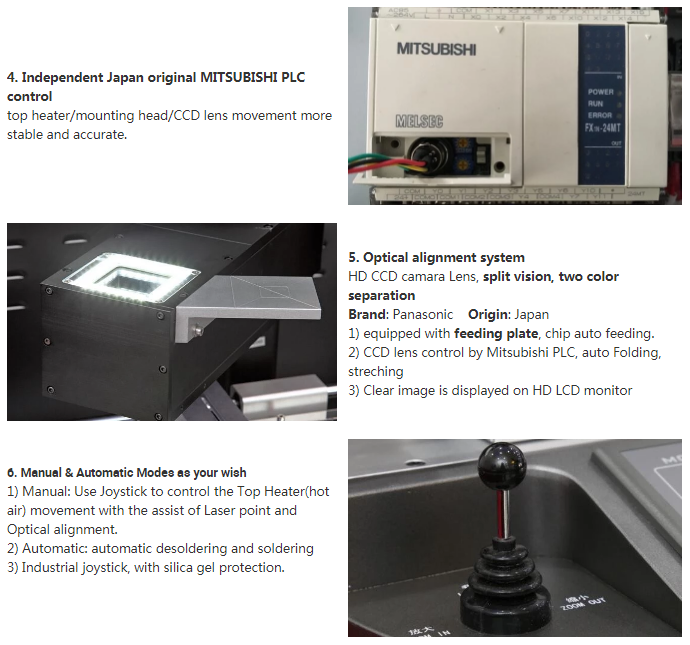

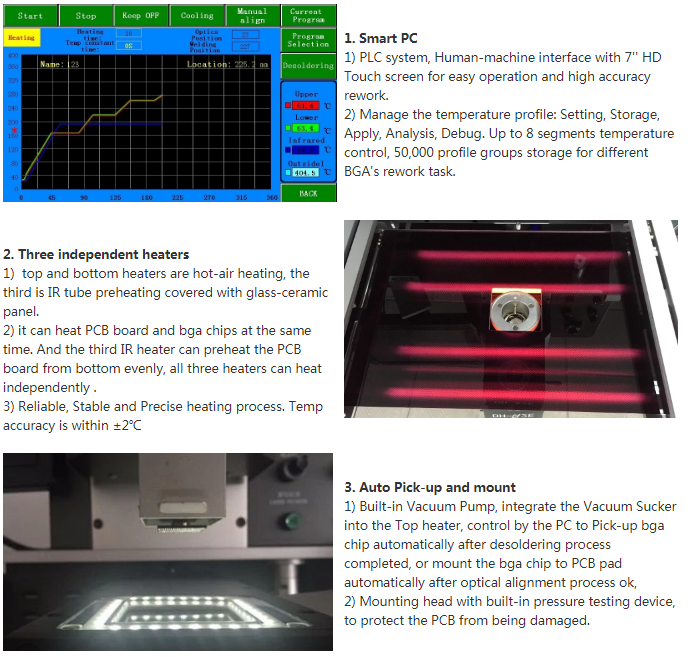

A CCD Camera Optical BGA Rework Station is a high-precision tool used for repairing BGA (Ball Grid Array) chips. It features a built-in CCD camera and optical alignment system to ensure accurate positioning of components. The camera allows real-time visual alignment between the chip and PCB pads, greatly improving accuracy and reducing the risk of misalignment. This type of station is ideal for delicate or high-density circuit board repairs where precision is critical.

GUIDED REWORK – Precision Meets Power

- Equipped with a high-efficiency 1200 W hot air upper heating head

- Focused and precise 1200 W lower hot air heating

- Large-area 2700 W infrared bottom heater for uniform heating

- Built-in vacuum pipette for easy component removal and placement

- Integrated force sensor for highly accurate component placement

- Enhanced visual guidance system for precise alignment

- Software-assisted positioning for optimized workflow

- Micrometer adjustment for fine-tuned placement accuracy

- Ideal for all types of chip-level repair and rework applications

2. Product Specifications

| Dimensions (W x D x H) in mm | 660 x 620 x 850 |

| Weight in kg | 70 |

| Antistatic Design (y/n) | Y |

| Power Rating in W | 5300 |

| Nominal voltage in V AC | 220 |

| Upper heating | Hot air 1200w |

| Lower heating | Hot air 1200w |

| Preheating area | Infrared 2700w, size 250 x330mm |

| PCB size in mm | from 20 x 20 to 370 x 410 (+x) |

| Component size in mm | from 1 x 1 to 80 x 80 |

| Operation | 7-inch build-in touch screen. 800*480 resolution |

| Test symbol | CE |

3. Product Applications

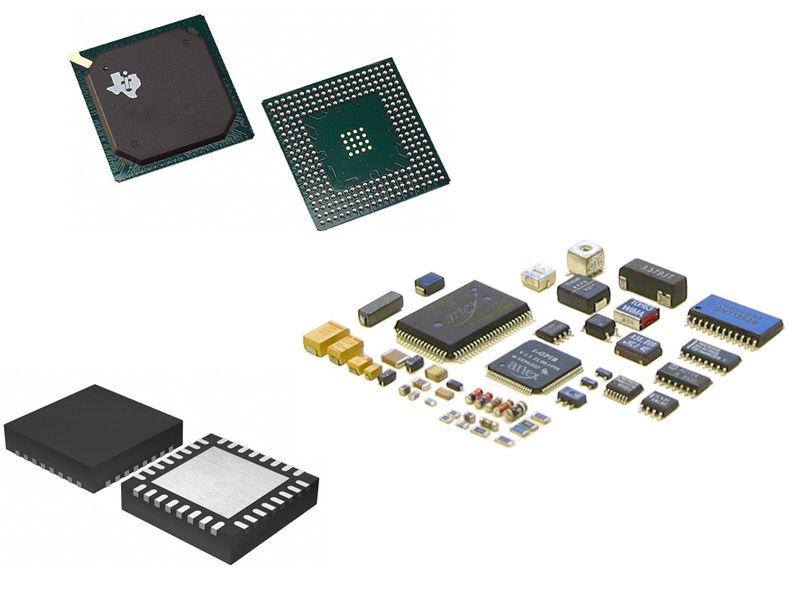

Our rework systems support a full range of SMD components - from ultra-small designs (008004) to large BGAs - with precise control over all process parameters to handle any challenge with confidence.

Designed for all SMD rework needs, ensuring reliable, good-as-new results for reworked components.

4. Product details

5. Product Qualifications

6. Our Services

At Dinghua, we provide a variety of technical and sales support services to both existing and prospective customers, including:

• Product data and information

• Installation and calibration support

• SMT/BGA rework process support

• Maintenance and warranty support

• Upgrade and software update support

7. FAQ

● I want to become an agent of SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO., LTD. Do you offer OEM service?

A: SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO., LTD. is looking for agents in different global markets. We have our own R&D department. OEM and ODM services are available. Business partners from all over the world are warmly welcome to visit our factory.

● What types of BGA rework machines does SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO., LTD. mainly produce?

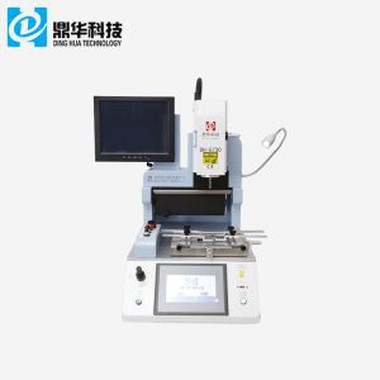

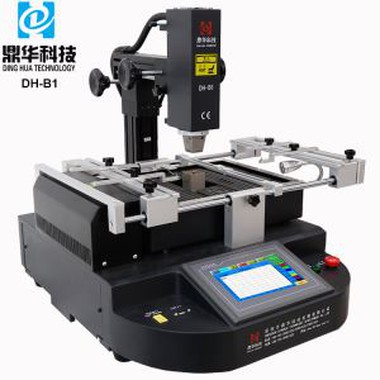

Main product categories include:

Keyboard BGA rework stations

Manual BGA rework stations with touch screens

Manual BGA rework stations with touch screens and optical alignment systems

Semi-automatic BGA rework stations with touch screens and optical alignment systems

Fully automatic BGA rework stations with touch screens and optical alignment systems

● How many nozzles do you offer?

A: We provide 3 top nozzles and 2 bottom nozzles. All nozzles are made of anti-rust titanium alloy. The top nozzle is designed with a reflow vent to protect surrounding components. The magnetic nozzle is easy to install, adjust, and replace.