Hot Air BGA Rework System

Dinghua BGA rework station DH-5830 is a hot air BGA rework system that used in laptop/mobile phone/IC/BGA/CPU motherboard repair. Equipped with three heater(2 hot air heater, 1 infrared preheater),three-zone independent temperature control system,HD touch screen,vaccum sucker pen,cross flow fan(for cooling),external temperature sensor,hot air adjustment.

Description

Products Description

This manual infrared BGA rework station DH-5830 is a hot air BGA rework system designed for soldering and desoldering BGA, SMD, and SMT components on printed circuit boards (PCBs). This manual BGA rework station provides precise temperature control and stable heating performance, making it ideal for PCB repair, motherboard rework, and chip replacement applications.

Equipped with infrared and hot air heating systems, this BGA rework machine ensures even heat distribution to prevent component damage. It is widely used in electronics manufacturing, repair centers, and R&D laboratories for BGA rework, SMD rework, and SMT repair tasks.

The manual BGA rework station features easy operation, cost-effective performance, and flexible adjustment functions-perfect for small-scale production lines or professional electronic repair workshops.

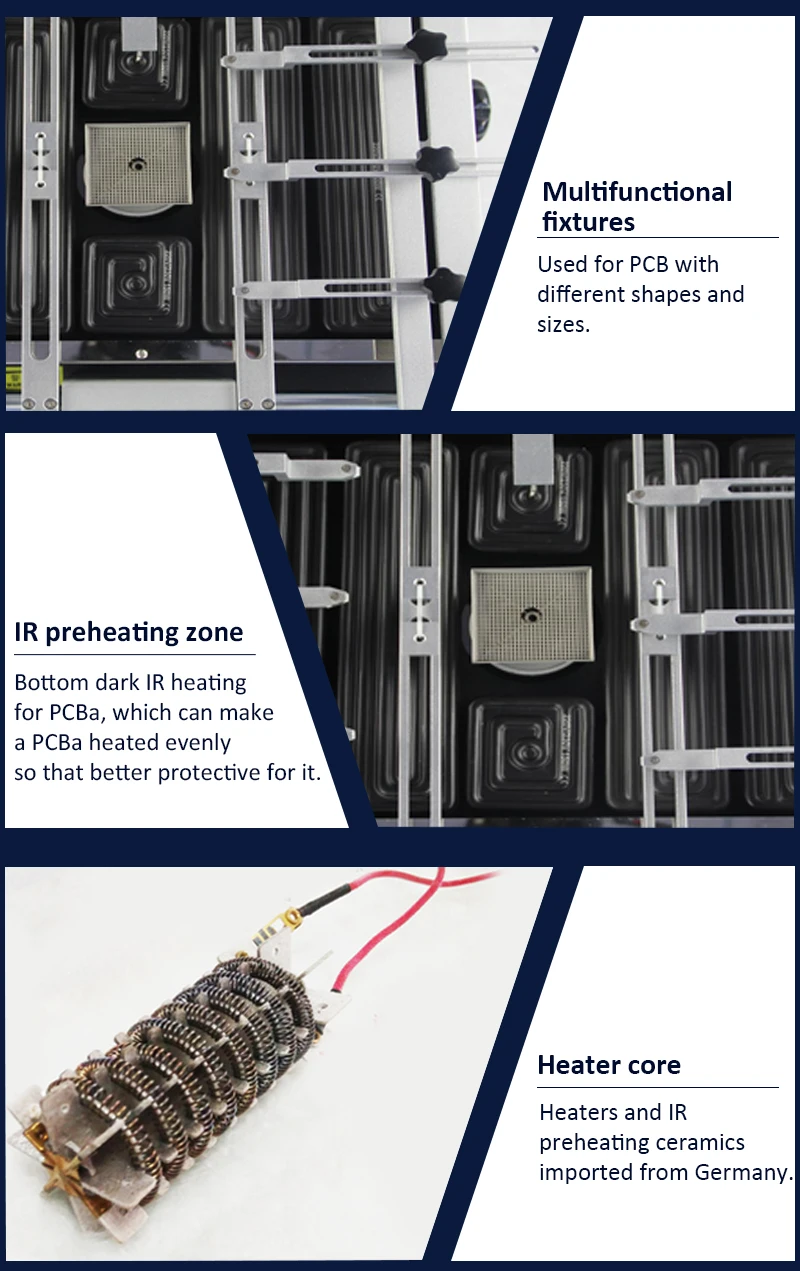

Humanized design:

1. Upper heater can move up/down, front/back, rotate freely.

2. Lower heater can move up/down to keep best distance with PCB.

3. Strong sense of thermometer, temperature measurement more accurate.

4. PCB clamp (V-groove) with universal fixture, suitable for all kinds of BGA.

5. It can set 8 segments heating, massive storage of temperature profiles.

6. With different size of nozzles, easy replace and use, customization is available.

7. Colorful buttons in English and Chinese, easy recognize and use.

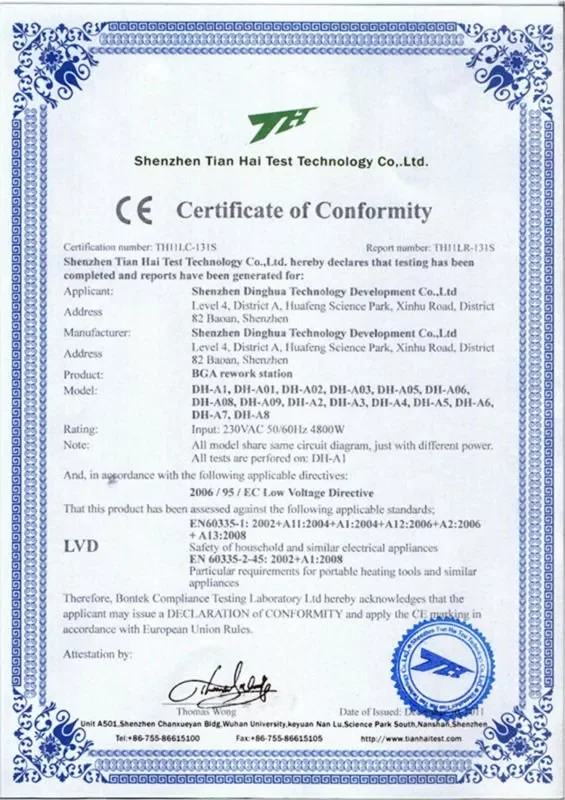

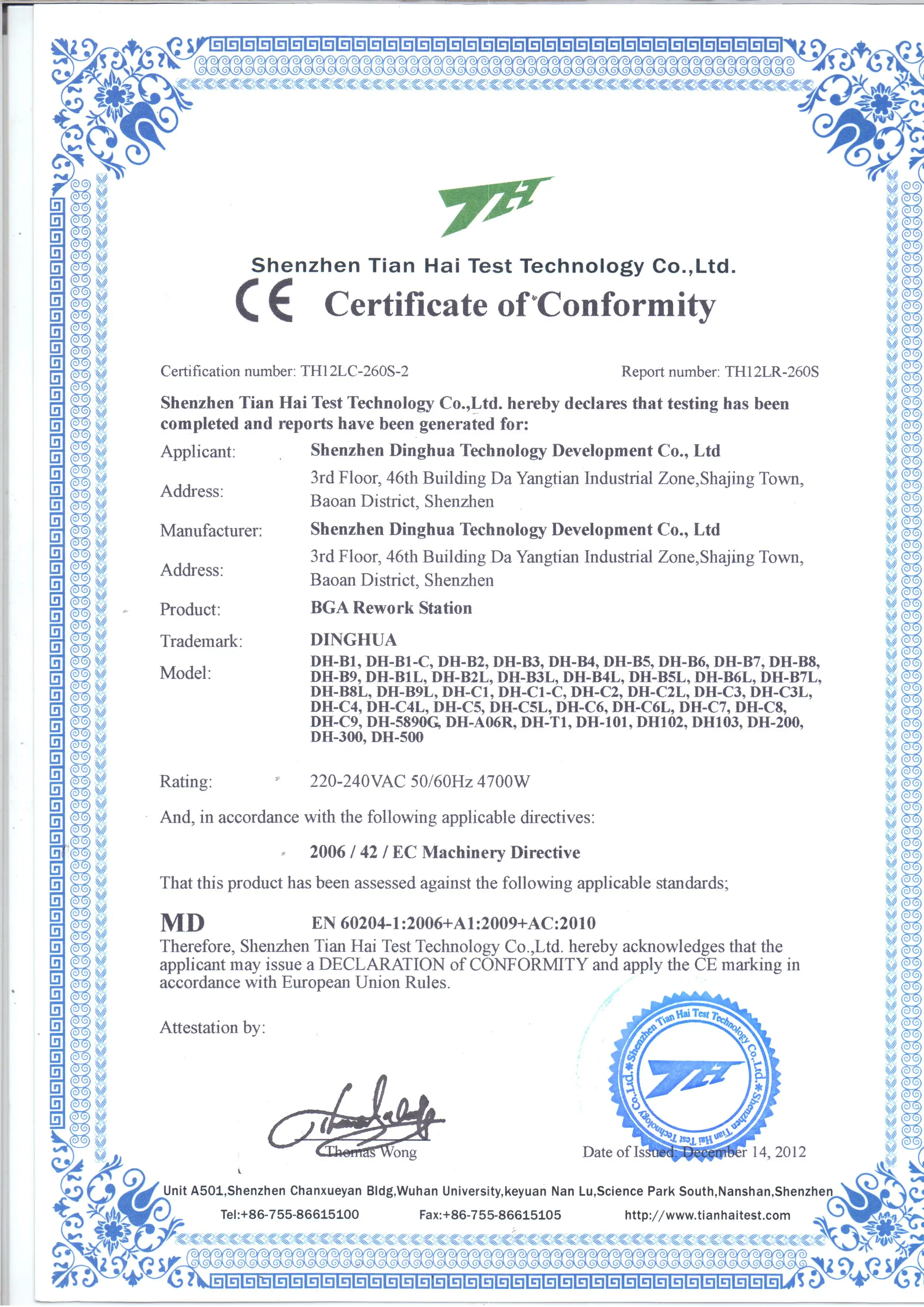

8. CE certification.

Products Specification

|

Item

|

Parameter

|

|

Power Supply

|

AC220V±10% 50Hz

|

|

Rated Power

|

5500W

|

|

Top Power

|

1200w

|

|

Bottom Power

|

1200w

|

|

Infrared Power

|

3000w

|

|

Top air-flow knob

|

For upper hot-air flow adjusting(especially, very small/big chips)

|

|

Operation Mode

|

HD touch screen, digital system setting

|

|

Temperature Profile Storage

|

50000 groups

|

|

Temperature Control

|

K Sensor + Closed Loop

|

|

Top heater movement

|

Right/left, frontward/backward, rotate freely

|

|

Temp accuracy

|

±2℃

|

|

Positioning

|

Intelligent positioning, PCB can be adjusted in X, Y direction with "5 points support" + V-groov pcb bracket + universal fixtures.

|

|

PCB size

|

Max 410×370 mm Min 22×22 mm

|

|

BGA chip

|

2x2 - 80x80 mm

|

|

Minimum chip spacing

|

0.15mm

|

|

External temper sensor

|

1pc

|

|

Dimensions

|

570*610*570mm

|

|

Net weight

|

35KG

|

Detail Images

Products Application

1. PCB and Motherboard Repair

Removing and resoldering BGA chips on computer, laptop, and mobile phone motherboards.

Fixing soldering defects such as cold joints, bridges, or insufficient solder.

2. Electronics Manufacturing and Rework

Used in SMT production lines for reworking defective PCBs.

Ideal for small-batch assembly, reballing, or component replacement.

3. R&D and Laboratory Testing

Used by engineers for circuit development, prototype testing, and functional debugging.

Enables precise temperature control for delicate components.

4. Maintenance and Training Centers

Used in repair centers, technical schools, and training institutes for soldering practice and demonstrations.

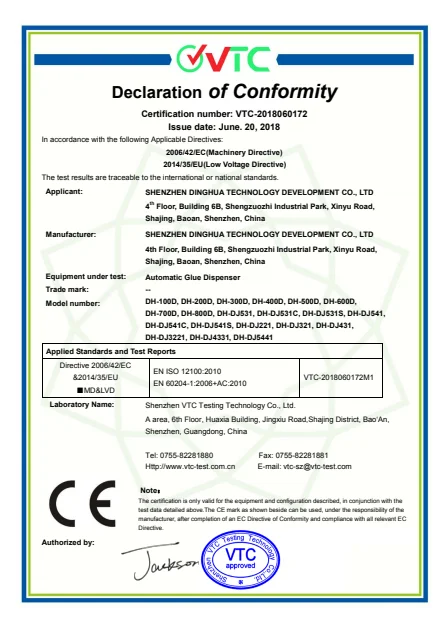

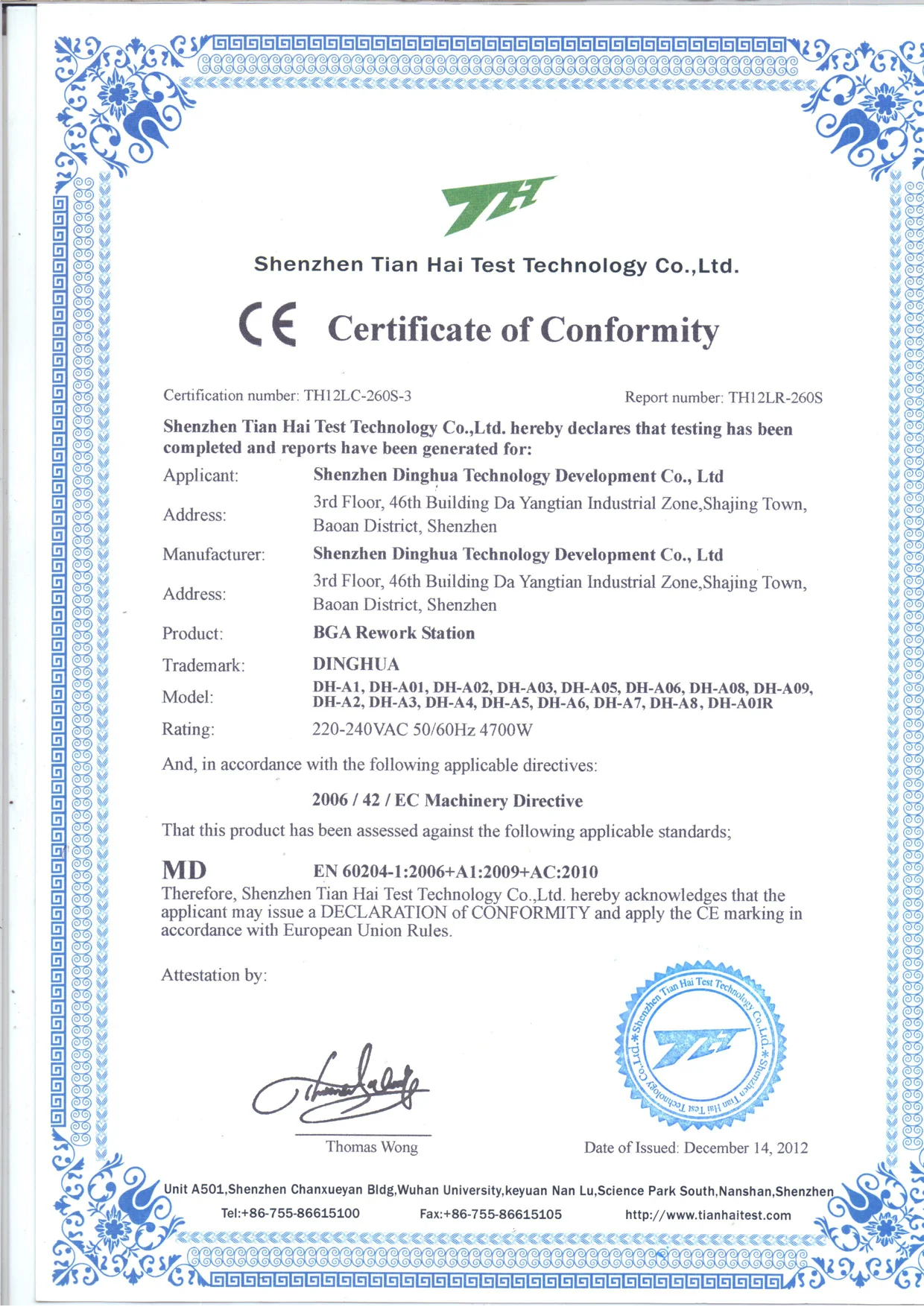

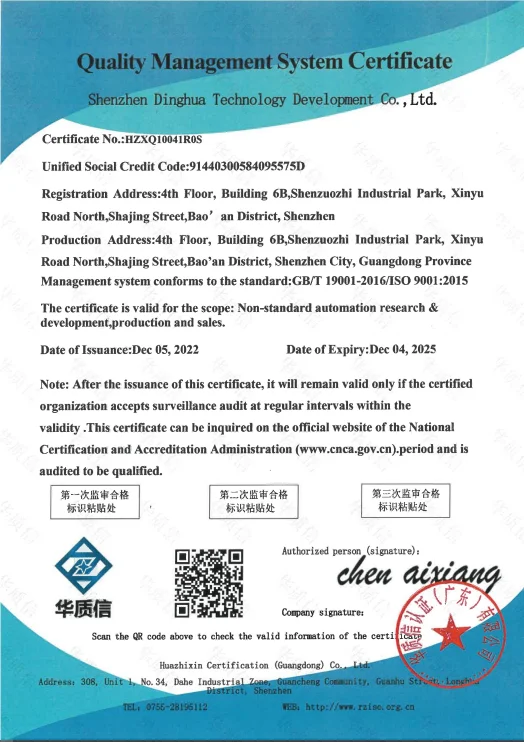

Company Profile

SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO., LTD is a national high-tech enterprise integrating R&D, production, sales and service. It is a professional manufacturer of non-destructive flaw detection equipment such as professional BGA rework station, X-ray inspection machine, X-ray counting machine and so on. We have the strength to provide you with better products, better services and more advanced technological productivity.

Dinghua has achieved significant milestones by obtaining various quality certifications such as UL, E-MARK, CCC,FCC, CE ROHS, ISO,GMP, FCCA, and C-TPAT. With over 38 patents, we have innovated manual, semi-auto, and automatic series, marking a transition from traditional hardware to integrated control.

Our products enjoy global recognition, being exported to over 80 countries and regions. Dinghua has established a robust sales network and terminal services system, making them a pioneer and guide in the SMT soldering industry.

Our products find applications in diverse sectors like individual maintenance, industrial and mining enterprises, teaching and research, and aerospace, earning a good reputation among users. Believing that clients' successes is our own, Dinghua strives to work together to build a better future.

Certifications

Why Choose Us

Strong Technical Competence

We have a professional R&D team and advanced manufacturing facilities to develop high-performance BGA rework stations, X-ray inspection machines, and other SMT equipment to meet various market needs.

Over 10 Years' Experience

We have built up a wealth of experience in SMT rework, PCB inspection, and electronic assembly, offering a stable quality and consistent performance for all products.

Strict Quality Control

All machines undergo comprehensive testing and inspection prior to being delivered to ensure accuracy, durability, and long-term reliability.

Professionalized Service Team

Our technical professionals can provide comprehensive pre-sale consulting, training, and after-sale service to ensure smooth operation and customer satisfaction.

Worldwide Market Recognition

Our products have been exported to more than 80 countries and regions, with an excellent reputation for innovation, quality, and service in electronics manufacturing.

Custom fits are available

We can meet your production needs through our OEM/ODM services that help your SMT rework and inspection process be more efficient.

Continuous Innovation

With quality and technology as our core drivers, we perseveringly continue to invest in research and development of new-generation BGA rework stations and intelligent X-ray inspection systems to facilitate better precision, and automation, and result in greater productivity for the electronics manufacturing industry.

Choose us for professional technology, reliable quality, and dedicated service - your trusted partner in SMT rework and inspection solutions.