Automatic BGA Rework Machine

This automatic BGA rework machine features automatic control of heating, alignment, soldering, and placement processes, significantly reducing operator error and improving repair efficiency. Its upper and lower heaters can move freely and independently, allowing flexible positioning and making chip heating and reworking much more convenient.

Description

Products Description

The Automatic BGA Rework Machine DH-A6 is an high-end repairing machine made for the effective rework of Ball Grid Array (BGA) and Surface Mount (SMT) components on printed circuit boards (PCBs). With an optical positioner by CCD camera, the precise placement of chips is made sure by showing the solder balls and the PCB pads to the user and positioning them exactly in real time.

This BGA rework machine is automatically controlled during the process for heating, alignment, soldering, and placement, greatly minimizing operator error and maximizing repair efficiency. The upper and lower heaters are able to freely and autonomously move, with the position being flexibly positioned, making chip rework and chip heating greatly more convenient.

This professional-level system combines multiple temperature zones, infrared-hydro hot-air hybrid heaters, and up-to-the-minute temperature curve displays for even distribution and consistent soldering performance. It is found across the industry for high-value PCB repair work on laptops, smartphones, industrial control boards, and communications.

Key Features & Advantages:

1. CCD Optical Alignment System → Delivers high-precision chip-to-pad alignment.

2. Automatic Operation → Reduces manual errors and ensures consistent rework quality.

3. Upper & Lower Heaters with Free Movement → Flexible positioning for convenient and efficient chip heating.

4. Multiple Temperature Zones → Independent control of top, bottom, and preheating zones for stable reflow.

5. HD Touch Screen Interface → Simple operation with real-time process monitoring.

6. Vacuum Pick-Up System → Safe and easy handling of BGA and SMT components.

7. Infrared + Hot Air Heating → Ensures even heat distribution and prevents PCB damage.

Products Specification

|

Item

|

Parameter

|

|

Power Supply

|

AC220V±10% 50/60Hz

|

|

Rated Power

|

6800W

|

|

Top heater

|

1200W

|

|

Bottom heater

|

1200W

|

|

IR preheating area

|

4200W (Germany heating tube, heating area of 500*350mm)

|

|

Operation mode

|

Fully automatically disassemble,suction,mounting and soldering

|

|

Chip feeding system

|

Automatic receiving, feeding, automatic induction (optional)

|

|

Temperature profile storage

|

50000 groups

|

|

Temperature control

|

K-type Sensor,Closed loop and 8~20 segments for temperature controlling program

|

|

Temperature accuracy

|

±1 ℃

|

|

Placement Accuracy

|

+/-0.01mm

|

|

Safety guard

|

pressure sensor +emergency knob,double-guard

|

|

PCB size

|

Max490*550 mm Min 10*10 mm

|

|

PCB thickness

|

0.2-15mm

|

|

BGA chip

|

1x1-65*65mm

|

|

Minimum chip spacing

|

0.15mm

|

|

External Temperature Sensor

|

5 pcs(optional)

|

|

Machine type

|

Desktop table (optional)

|

|

Dimensions

|

L970*W850*H950 mm

|

Product Features

Detail Pictures

Company Profile

SHENZHEN DINGHUA TECHNOLOGY DEVELOPMENT CO., LTD is a national high enterprise integrating the R&D, production, sales and service of X-ray counting machine, X-ray NDT machines, BGA rework stations, and automation equipment! We have absolute strength to provide you with high-quality products, perfect services and advanced technical support.

Our product range includes BGA rework stations, automatic soldering machines, automatic screwdriving machines, soldering kits, and SMT materials. Committed to excellence, our mission revolves around research, quality, and service, aiming to provide professional equipment, quality, and service.

Our products enjoy global recognition, being exported to over 80 countries and regions. Dinghua has established a robust sales network and terminal services system, making them a pioneer and guide in the SMT soldering industry.

Our products find applications in diverse sectors like individual maintenance, industrial and mining enterprises, teaching and research, military manufacturing, and aerospace, earning a good reputation among users. Believing that clients' successes is our own, Dinghua strives to work together to build a better future.

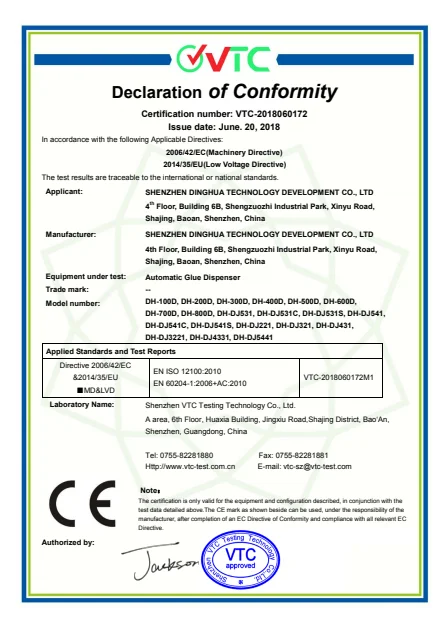

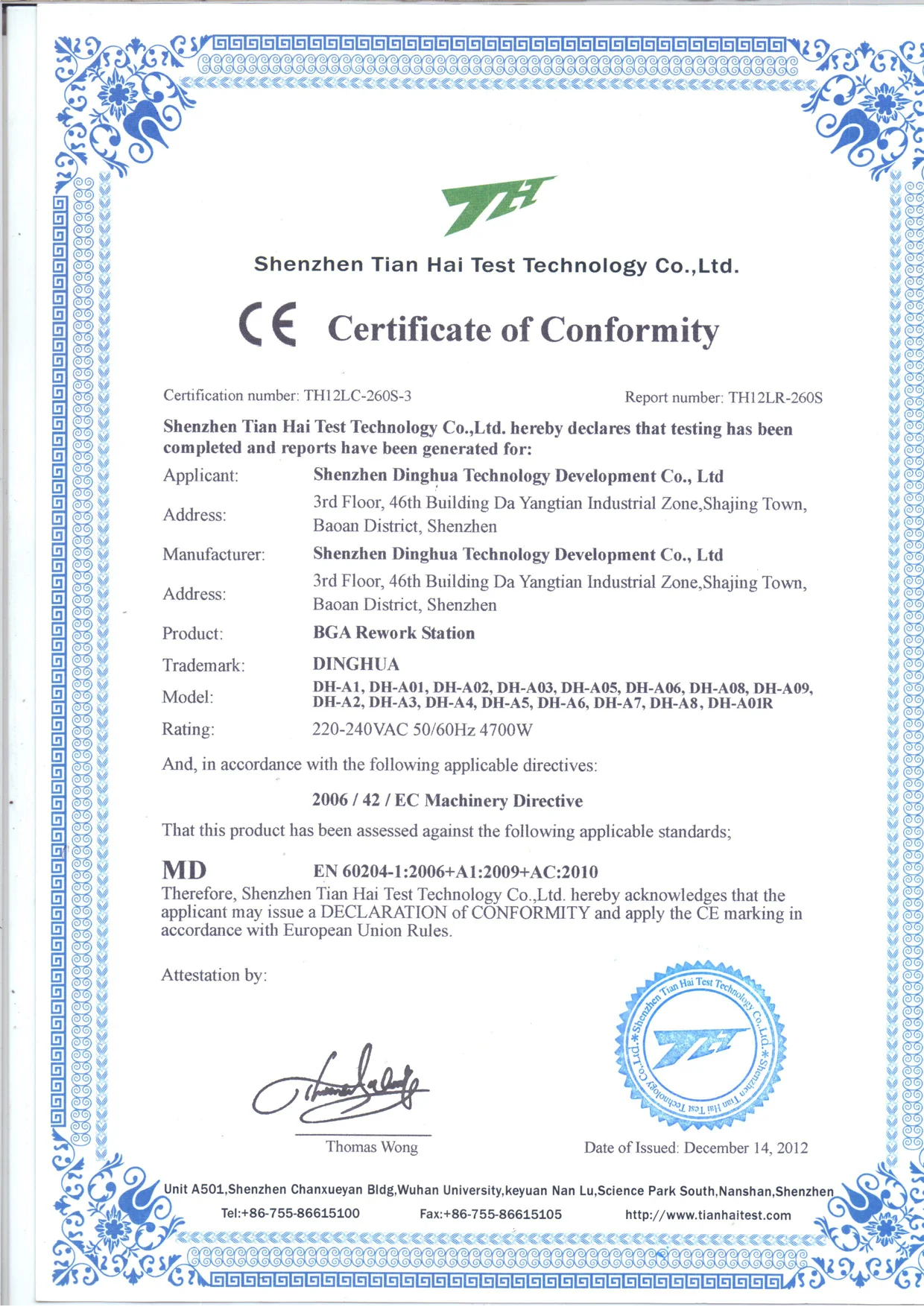

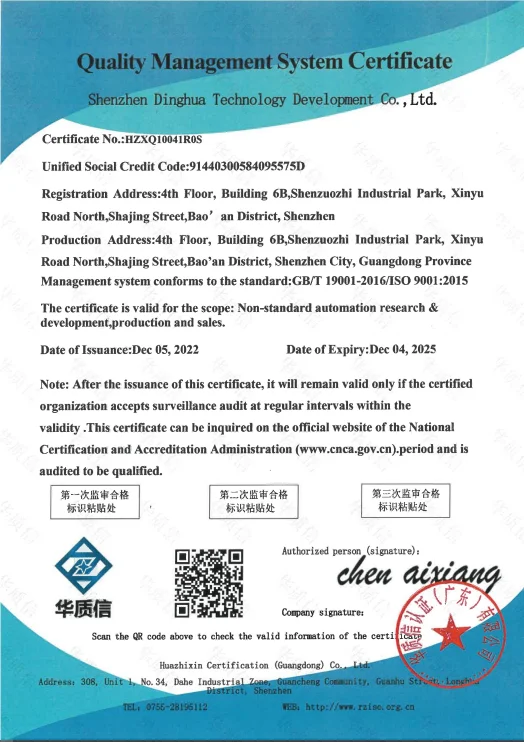

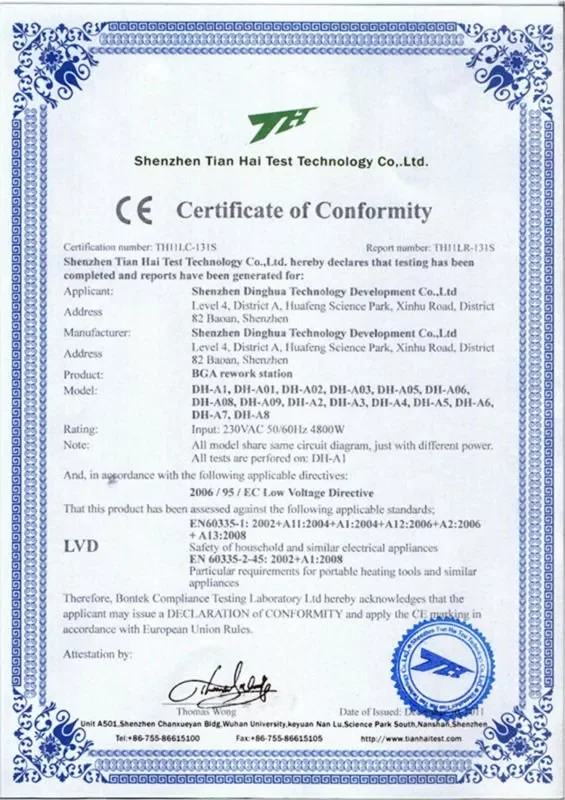

Certification