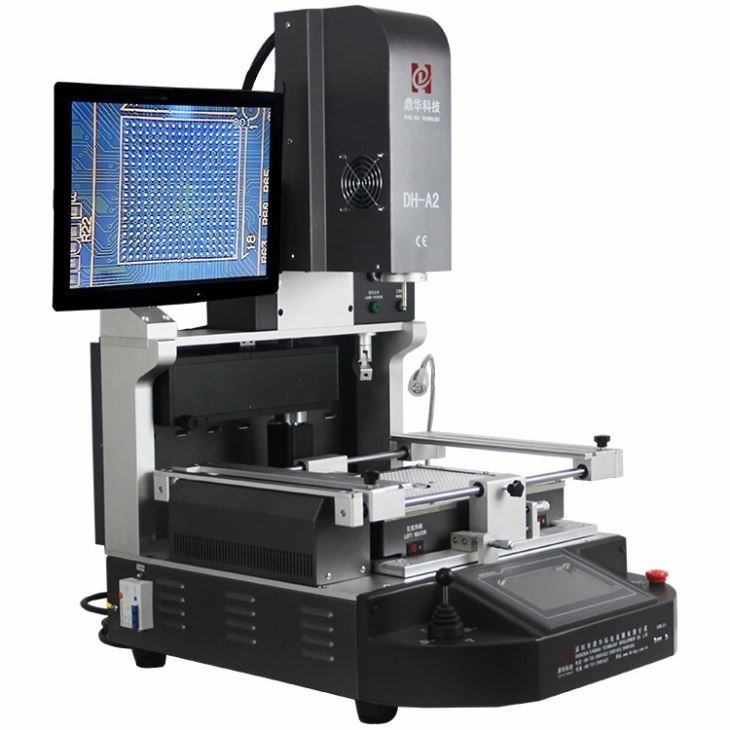

SMD BGA Infrared Soldering Station

Easy to operate. Suitable for chips and motherboard of different sizes. High successful rate of repairing.

Description

SMD BGA infrared soldering station

1.Application Of SMD BGA infrared soldering station

Suitable for different PCB.

The motherboard of a computer, smartphone, laptop, MacBook logic board, digital camera, air conditioner, TV and other electronic equipment from the medical industry, communication industry, automobile industry, etc.

Suitable for different kind of chips: BGA,PGA,POP,BQFP,QFN,SOT223,PLCC,TQFP,TDFN,TSOP, PBGA,CPGA,LED chip.

2.Product Features of DH-A2 SMD BGA infrared soldering station

• Desoldering, mounting and soldering automatically.

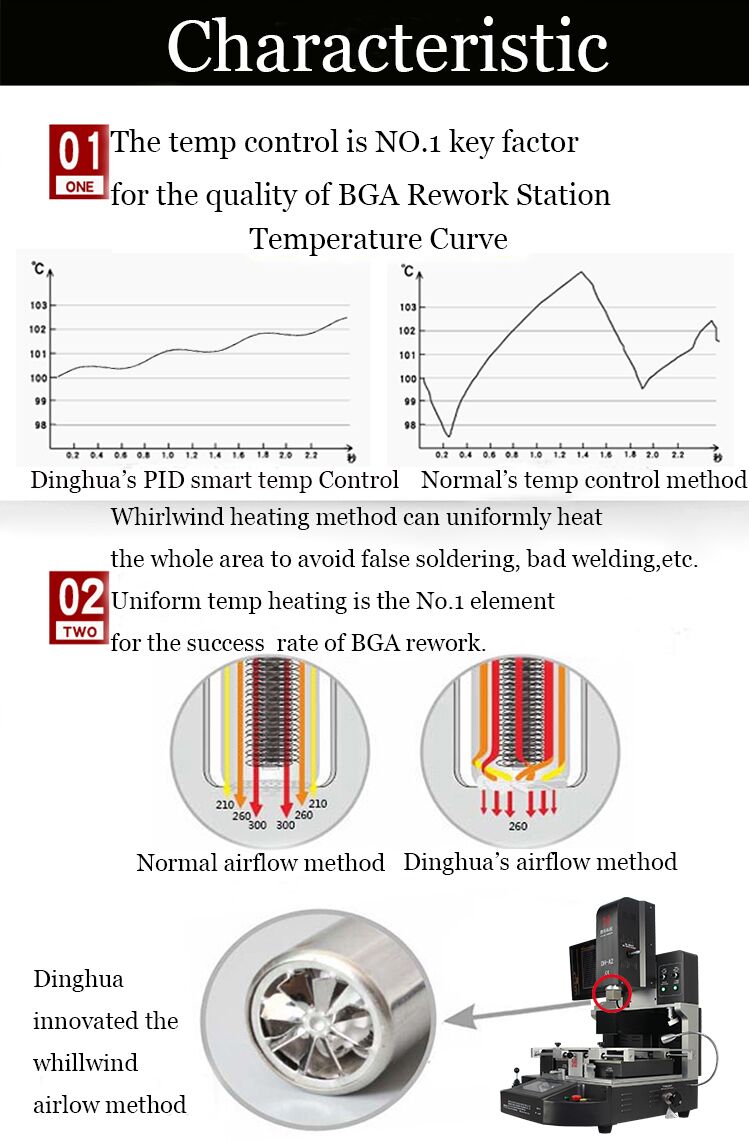

• Characteristic of high volume (250 l/min), low pressure (0.22kg/ cm2), low temp (220°C) rework completely guarantees BGA chips electricity and excellent soldering quality.

•Utilization of silent and low-pressure type air blower permits the regulation of silent ventilator, the airflow can be regulated to 250 l/Min the maximum.

•Hot air multi-hole round center support is especially useful for big-size PCB and BGA located in the center of PCB. Avoid cold soldering and IC-drop situation.

•The temperature profile of bottom hot air heater can reach as high as 300°C, critical for big size motherboard. Meanwhile, the upper heater could be set as synchronized or independent work

DH-G620 is totally same as DH-A2, automatically desoldering, pick-up, puting back and soldering for a chip, with optical alignment for mounting,no matter whether you have experience or not, you can master it in one hour.

3.Specification of DH-A2 SMD BGA infrared soldering station

| Power | 5300w |

| Top heater | Hot air 1200w |

| Bottom heater | Hot air 1200W. Infrared 2700w |

| Power supply | AC220V±10% 50/60Hz |

| Dimension | L530*W670*H790 mm |

| Positioning | V-groove PCB support, and with external universal fixture |

| Temperature control | K type thermocouple,closed loop control,independent heating |

| Temperature accuracy | ±2℃ |

| PCB size | Max 450*490 mm, Min 22 *22 mm |

| Workbench fine-tuning | ±15mm forward/backward,±15mm right/left |

| BGA chip | 80*80-1*1mm |

| Minimum chip spacing | 0.15mm |

| Temp Sensor | 1(optional) |

| Net weight | 70kg |

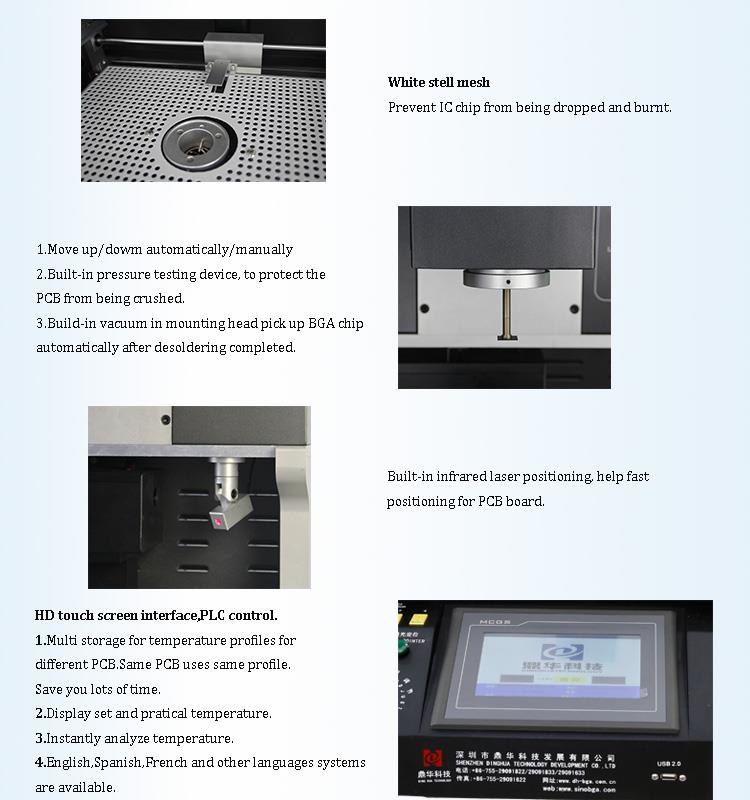

4.Details of DH-A2 SMD BGA infrared soldering station

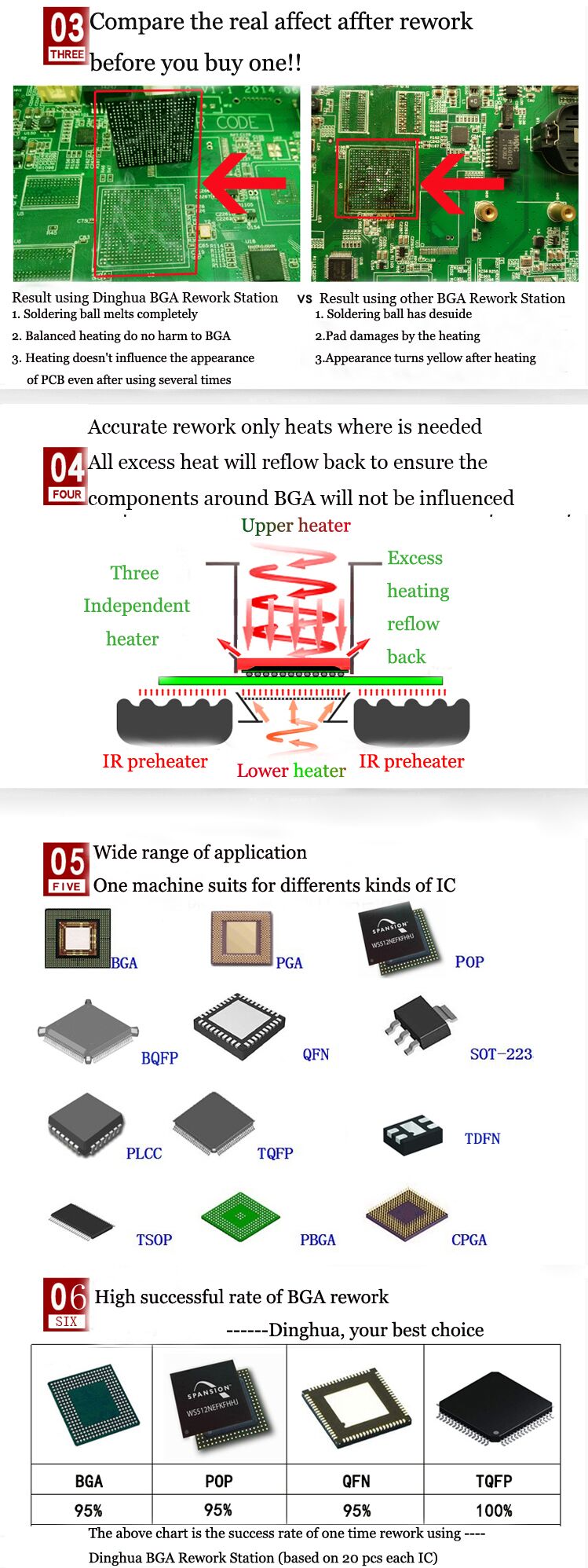

5. Why Choose Our DH-A2 SMD BGA infrared soldering station?

6.Certificate of DH-A2 SMD BGA infrared soldering station

7.Packing & Shipment of DH-A2 SMD BGA infrared soldering station

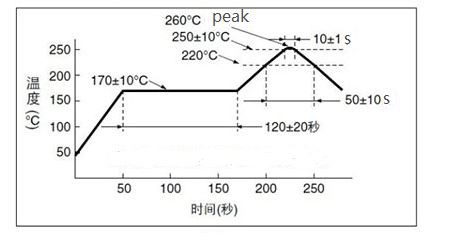

8.How to set temperatures for BGA chip lead-free for soldering

With the widespread use of chips, we have also paid more and more attention to the problem of chip rework. Currently, there are two main types of BGA chips used in the market. One is leaded, the other is lead-free, leaded and lead-free BGA chip soldering process temperature settings are different, so how appropriate is the lead-free BGA chip soldering process temperature setting? Next Dinghua Technology Xiaobian will give you a detailed introduction.

Under normal circumstances, the temperature requirements for lead-free BGA chips are very strict during soldering. The temperature at which the melting point of lead-free BGA chips is about 35 degrees higher than the melting point of lead-free BGA chips. Lead BGA chips need to understand its characteristics before soldering. Generally speaking, the melting point of lead-free reflow soldering varies according to the lead-free solder paste. Here we give two values as a reference. The melting point of tin-silver-copper alloy is about 217 degrees, and the melting point of solder paste of tin-copper alloy is about 227 degrees. Below these two temperatures, solder paste cannot be melted due to insufficient heating. When buying a BGA rework station, you also need to pay attention to consulting the manufacturer about the heating temperature of the lead-free BGA chip. Whether the device can meet the temperature. If not, you need to consider whether to buy. Generally, the temperature in the lead-free furnace should be about 10 degrees. The following is a detailed introduction:

| Alloying ingredient | melting point(℃) |

| Sn99Ag0.3Cu0.7 | 217-221 |

| Sn95.5Ag4Cu0.5 | 217-219 |

| Sn95.5Ag3.8Cu0.7 | 217-220 |

| Sn95.7Ag3.8Cu0.5 | 217-219 |

| Sn96.5Ag3Cu0.5 | 216-217 |

| Sn98.5Ag0.5Cu1 | 219-221 |

| Sn96.5Cu3.5 | 211-221 |

| Sn99Cu1 | 225-227 |

When operating lead-free BGA chip soldering, we generally use the entire sheet metal to make the furnace cavity, which can effectively ensure that the furnace cavity does not warp at high temperatures. However, there are many bad manufacturers who use small pieces of sheet metal to splice into the furnace cavity in order to compete for the price. This kind of equipment is generally invisible if you do not pay attention to it, but warp damage will occur if it is under high temperature.

The lead-free BGA chip is also essential for testing the parallelism of the track during high temperature and low-temperature operation before soldering because this will directly affect the soldering success rate of the BGA chip. If the materials and design of the purchased BGA rework equipment cause the track to be easily deformed under high-temperature conditions, it will cause card jamming or dropping. The conventional Sn63Pb37 leaded solder is a eutectic alloy, and its melting point and freezing point temperature are the same, both of which are 183 ° C. The lead-free solder joints of SnAgCu are not eutectic alloys, and their melting points range from 217 ° C to 221 ° C, temperatures below 217 ° C are solid, and temperatures above 221 ° C are liquid. When the temperature is between 217 ° C and 221 ° C The alloy showed an unstable state