Bga Rework Station Machine

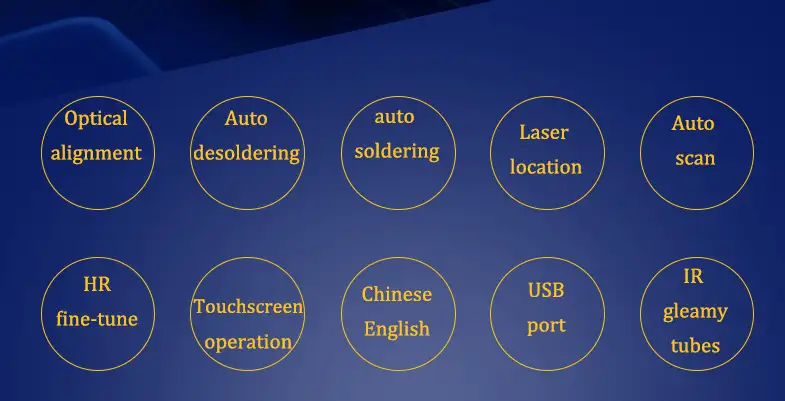

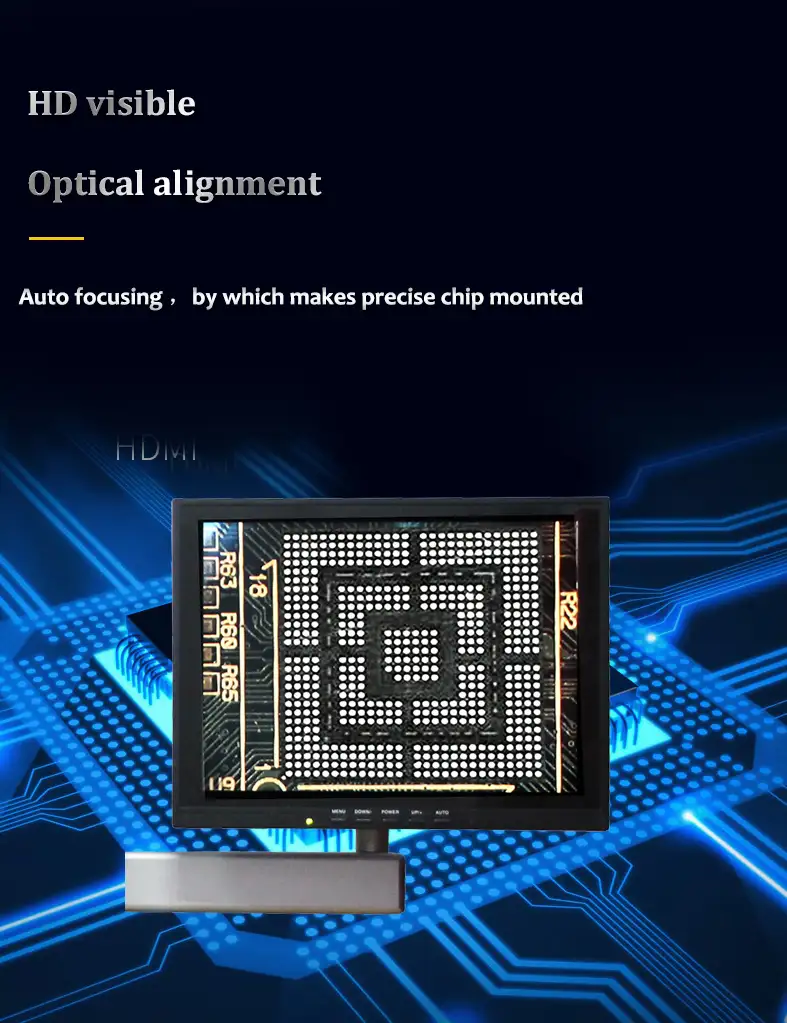

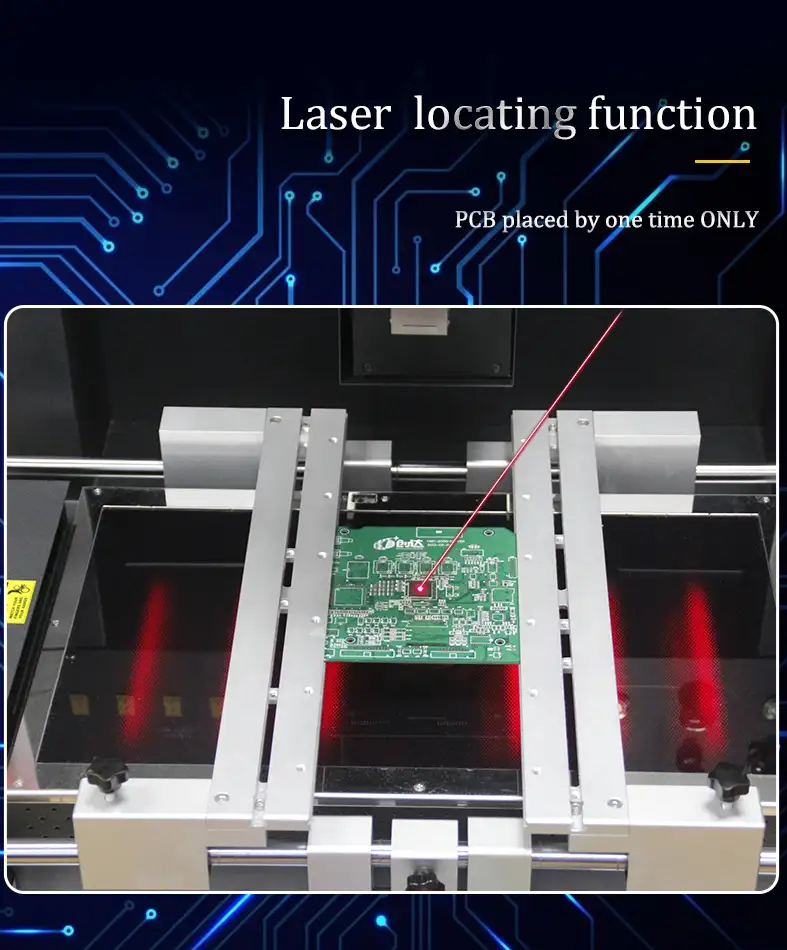

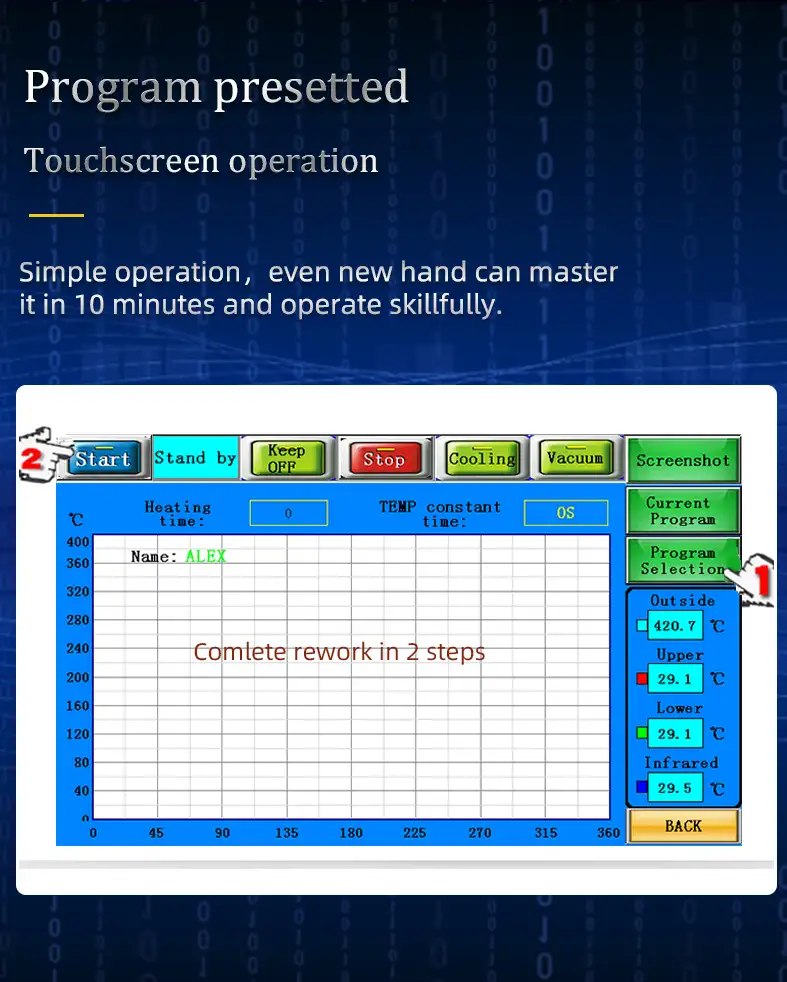

Fully automatic optical alignment, laser positioning, and automatic chip removal, soldering as well as mounting. It features a bilingual Chinese-English touch screen interface for easy operation. Keywords:laser bga rework station ic repair,infrared bga rework station, bga infrared rework station

Description

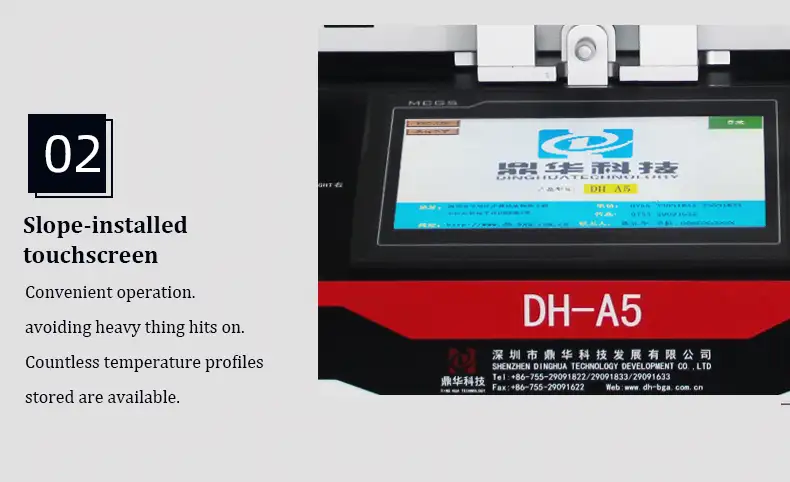

DH-A5 Automatic BGA rework station

As the best choice for multinational companies, the need for high-quality and efficient BGA rework stations is more urgent than ever.

This is especially true for cross-border companies that must adapt to different manufacturing environments while maintaining quality

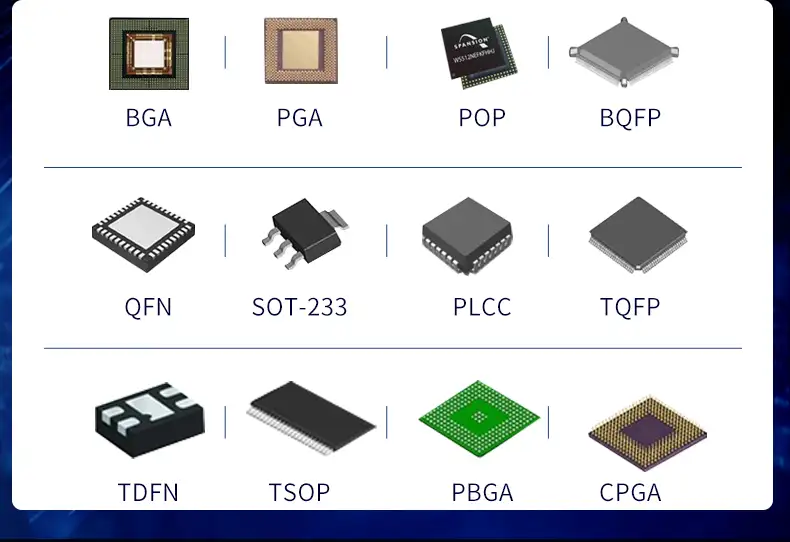

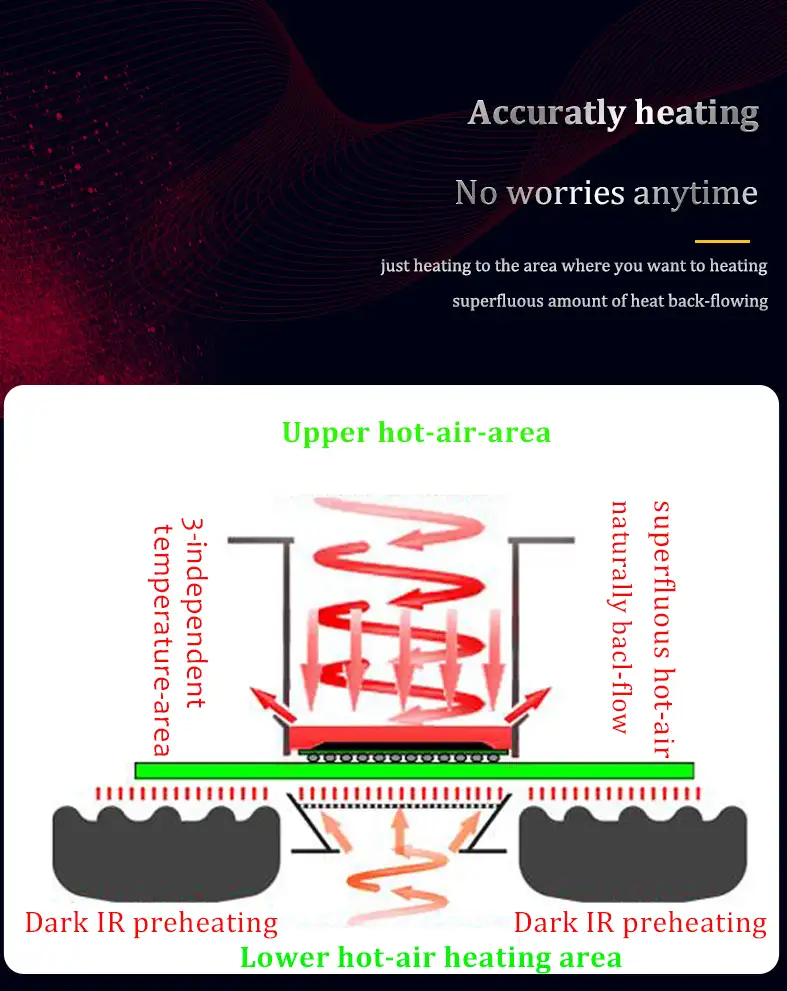

standards.The upgraded DH-A5 automatic infrared bga rework station is the perfect solution for these companies. Through profiling and better configuration, the bga infrared rework station provides precise and automated rework processes for BGA, CSP, QFN and other SMD components, trusted by the world's leading technology companies, including Google, Micron, Foxconn and Huawei. With its advanced features and performance, it is the first choice for BGA rework in the most demanding situations. Profiling for precise and consistent results One of the key features of the DH-A5 is its advanced profiling capabilities.

Products Parameters

| Rated power | 6200W |

| Upper power | 1200W |

| Bottom power | The 2nd heating: 1200W, 3rd heating: 3600W |

| Power supply | AC 110~250V 50/60Hz |

| Mounting accuracy | ±0.01mm |

| PCB fixed | V-groove, bracket moved at X/Y, and with fixtures |

| Temperatrue controlling | Cloosed loop, PID and K-type sensor |

| PCB size | Max 570*640mm, Min 10*10mm |

| Platform fine-tune | Front/Back:+/-15mm, left/right::+/-15mm |

| Temperatrue accuracy | +/-1 °C |

| Zoom in | 1~100 times |

| Chip size | 1*1~80*80mm |

| Min Space | 0.1mm |

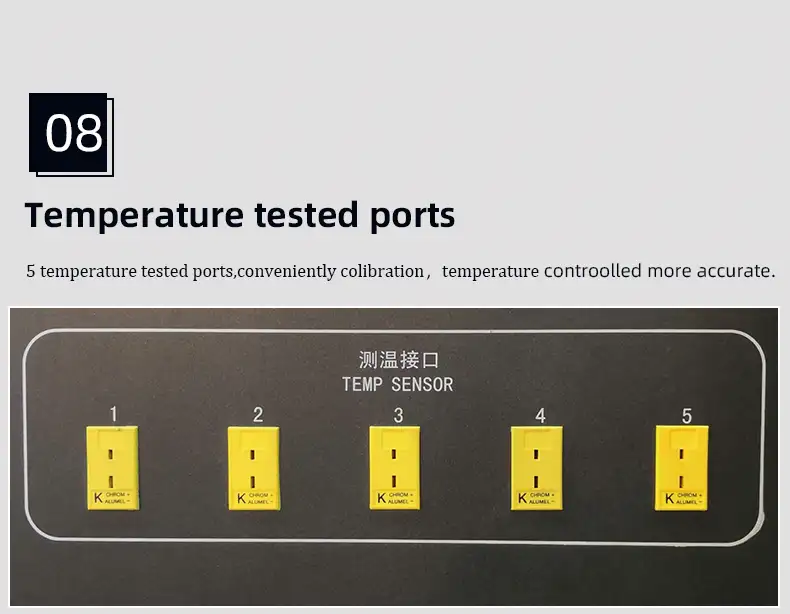

| External temperatrues' ports | 5 pcs(optional) |

| Dimension | 650*700*850mm |

| Net weight | 92kg |

laser bga rework station ic repair

This feature allows the machine to analyze the heat distribution of components and adapt to the specific requirements of the

rework process. No matter the size or complexity of the component, the results are precise and consistent every time. Better

configuration increases efficiency, and in addition to its contour analysis capabilities, the DH-A5 also boasts a range of other

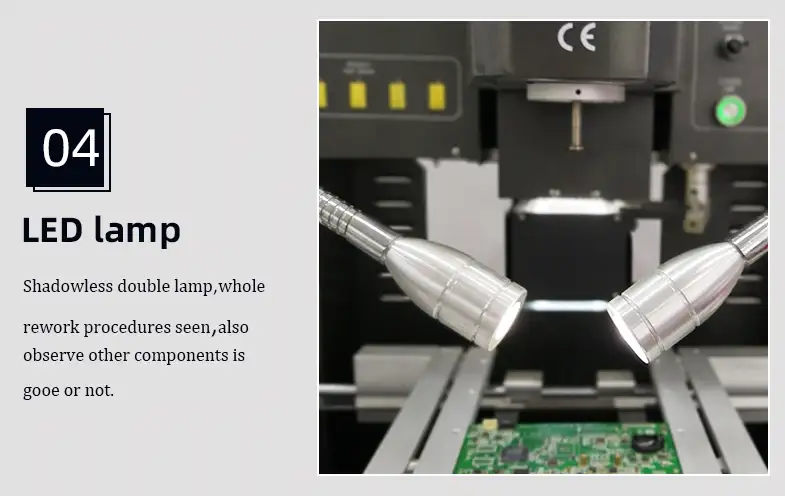

advanced features that contribute to its superior efficiency. These include a high-resolution camera for precise alignment of

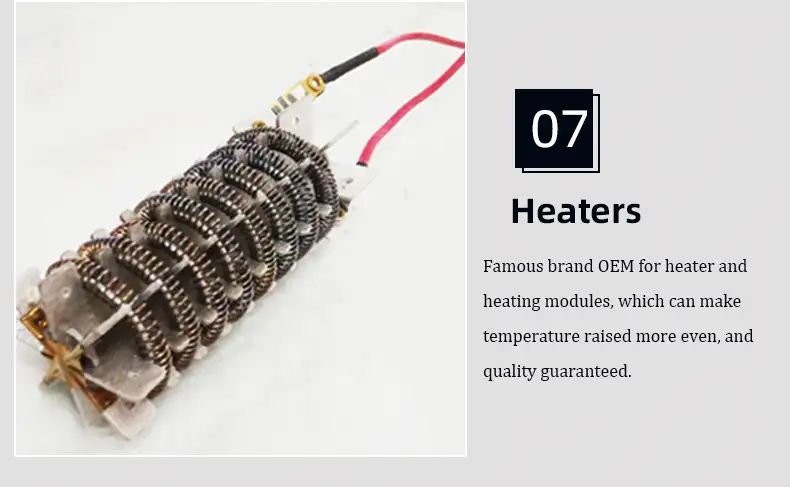

components, and a high-power heating system capable of reaching temperatures up to 350°C.

The DH-A5 Automatic BGA Rework Station is the ideal solution for cross-border companies looking for a BGA rework station that

can adapt to any manufacturing environment while maintaining high quality standards. Through profile analysis and better configuration,

it ensures precision, consistency and efficiency, making it the first choice for rework in the most demanding situations.

One of the most important aspects of a BGA rework machine is its precision. The temperature control needs to be accurate within a very narrow range. If the temperature is too high, it can damage the PCB or other components; if it is too low, the solder may not melt properly, leading to a poor connection. The alignment system also has to be highly precise. A misaligned BGA can result in short - circuits, open - circuits, or other electrical problems.

The BGA rework machine has wide - ranging applications. In the consumer electronics industry, it is used to repair smartphones, tablets, and gaming consoles. In the computer industry, it is employed for motherboard repair and upgrades. Moreover, in the industrial and military - grade electronics sectors, where high - reliability components are used, the BGA rework machine is used to maintain and repair complex electronic systems.

As electronics continue to evolve, BGA rework machines are also expected to improve. There will likely be advancements in temperature control technology, alignment accuracy, and overall automation. This will make the rework process even more efficient and reliable, reducing the cost and time associated with BGA - related repairs.

Our Company

Customer Transaction