Bga Rework Tools

It features optical alignment, automatic disassembly, automatic welding, automatic component placement, precise temperature control, and over-temperature protection to prevent PCB deformation. It has a large preheating area, safety light curtains, and is easy to operate. Key Words:fully automatic bga rework station,bga ic rework station,best bga rework station

Description

When a single failed BGA threatens a high-value assembly, you need more than a repair-you need guaranteed recovery. Our industrial BGA Rework Station isn't just equipment; it's your insurance policy against costly scrap and downtime, engineered to deliver flawless, repeatable results on the most demanding PCBs.

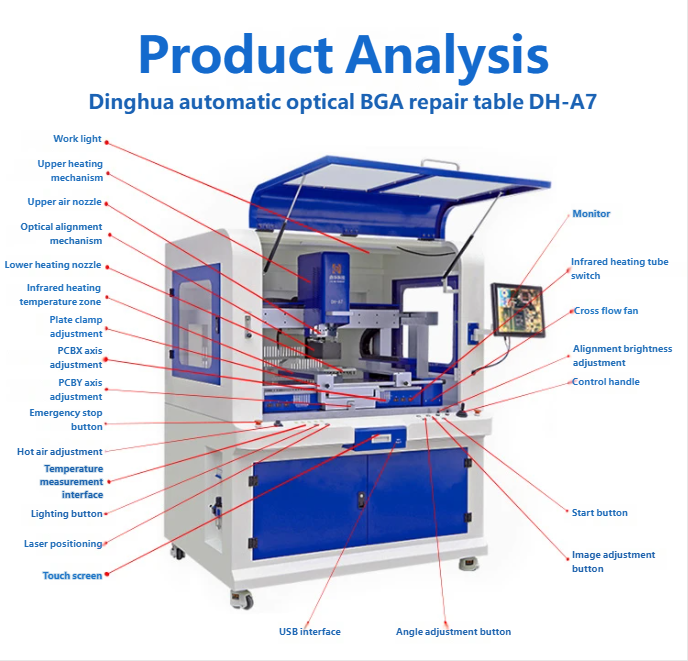

DH-A7 Fully automatic bga rework station

Products Discription

1.The Precision Salvage Tool:Our micro-alignment vision system and stabilized platform let you remove and replace 0.25mm pitch BGAs with confidence, saving thousands in component and board costs. --- fully automatic bga rework station

2.Multi-zone controllable temperature profile:Programmable, multi-zone thermal profiles apply the exact same heat to every board, ensuring every rework meets the same standard as your first-run production-critical for automotive. --- bga ic rework station

3.Closed-Loop Control System:This prevents board warping and damage. --- best bga rework station

Products Parameters

| Total power | 11500W |

| Top heater | 1200W |

| Lower heater | 1200W |

| Bottom heater | 9000W (German heating element, heating area 860×635) |

| Power supply | AC380V±10% 50/60Hz |

| Dimensions | L1460×W1550×H1850 mm |

| Operation mode | Automated desoldering, soldering, suction, and placement in one integrated system. |

| Temperature profile storage | 50,000 sets |

| Optical CCD lens | It extends and retracts automatically, and can be freely moved forward, backward, left, and right via a joystick, eliminating the problem of "blind spots" during observation. |

| Positioning | V-shaped card slot, PCB support bracket is adjustable in the X direction and comes with a universal clamp. |

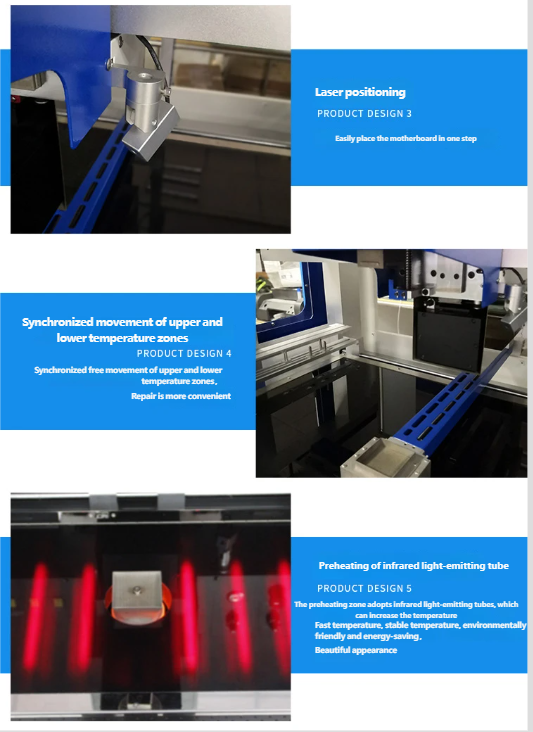

| BGA position | Laser positioning allows for quick identification of the vertical points of the upper and lower temperature zones and the center of the BGA. |

| Temperature control | K-type thermocouple (K Sensor) , Closed-loop control |

| Temp accuracy | ±3 degrees |

| Repeatable placement accuracy | +/-0.01mm |

| PCB size | Max 900×790 mm Min 22×22 mm |

| BGA chip | 2×2-80×80mm |

| Minimum chip spacing | 0.25mm |

| External Temperature Sensor | 5 |

| Net weight | 820kg |

Products Details

Products Advantages

1.Increased preheating area, capable of repairing large-size motherboards with dimensions of 900×790 MM;

2.The upper and lower temperature zones move freely synchronously, making repair more convenient;

3.Optical alignment ensures precise positioning for chip mounting, completely avoiding misalignment and deviation;

4.Automatic picking & removal, automatic welding, and automatic chip recycling fully liberate workers; (bga ic rework station)

5.The preheating zone adopts infrared light-emitting tubes, featuring fast heating, stable constant temperature, environmental protection, energy saving, and an attractive appearance;

6.Touch screen operation with pre-built programs allows proficient use without special technical training, making chip repair extremely simple;

7.External USB port for software updates/upgrades and importing various repair data into computers for analysis and storage;

8.Automatic scanning after repair completion to ensure repair quality, it's the best bga rework station for enterprise;

9.Suitable for repairing various SMT components {SOP, SOJ, QFP, QFN, BGA, PLCC, SCP……};

10.Optional function to connect to the MAS system.

Prove It on Your Board: Skeptical? We get it. Request a live, online demonstration. Ship us a sample board with a known BGA failure. We'll conduct a live rework procedure via video link, showing you the entire process and the final, functional result.

Our Company

Customer Transaction